Product detail

Zircon bricks for cement kilns

Product introduction

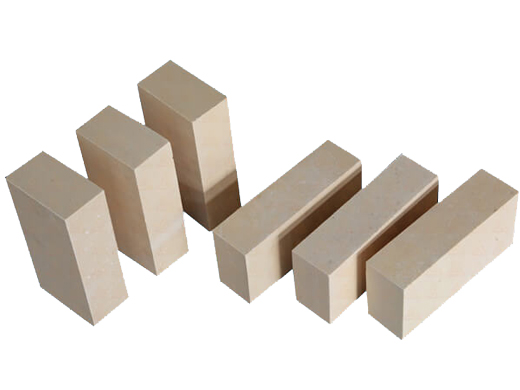

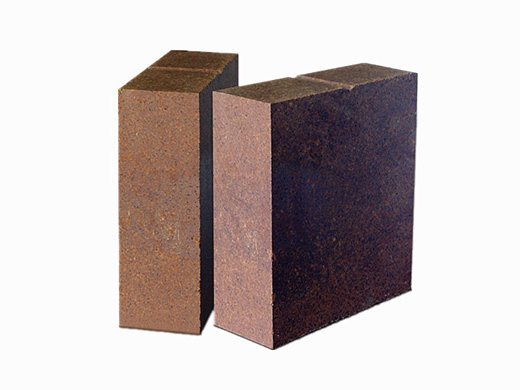

Zircon bricks for cement kilns are refractory materials made of high-quality zircon as the main raw material and fired at high temperature. It has excellent high temperature resistance and can withstand the high temperature environment in the cement kiln. The long-term use temperature can reach more than 1600℃. It has good thermal stability and is not easy to crack when the temperature changes sharply. At the same time, the brick also has strong corrosion resistance and can effectively resist the corrosion of alkaline substances and acidic gases in cement clinker, thereby maintaining the structural integrity of the kiln lining, extending the service life, and ensuring the continuity and stability of cement production.

Application

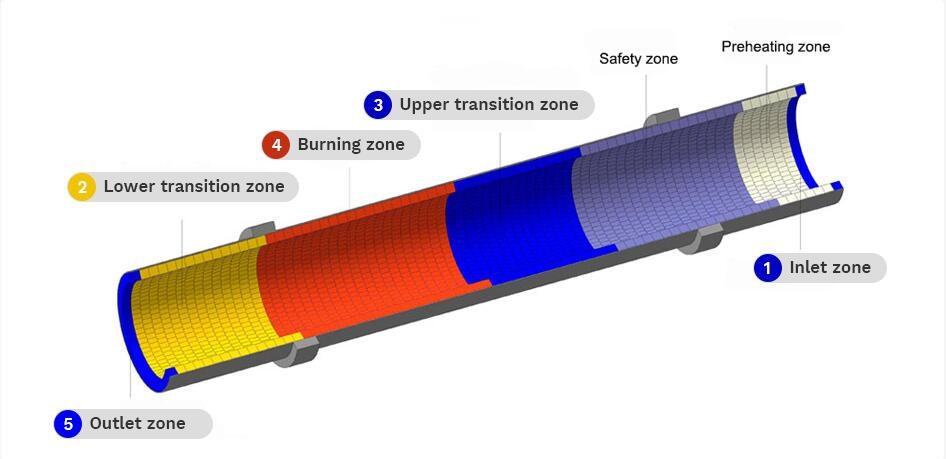

In the cement industry, zircon bricks are mainly used in key parts such as the firing zone and transition zone of cement kilns. The firing zone is the core area of cement clinker calcination, with high temperature and severe chemical erosion. Zircon bricks can maintain good performance under this harsh condition to ensure the quality and output of clinker. The temperature and atmosphere in the transition zone vary greatly. The thermal stability and corrosion resistance of zircon bricks enable them to adapt to such complex working conditions, providing reliable guarantee for the efficient and stable operation of cement kilns, helping to improve cement production efficiency, reduce production costs, and enhance the quality and market competitiveness of cement products.

Product Parameters

| Ingredients | Content range | Function |

| ZrO₂ (zirconium oxide) | 60%-65% | Provides high temperature stability and corrosion resistance, is the key component of zircon bricks, enhances the high temperature resistance and chemical corrosion resistance of the brick body. |

| SiO₂ (silicon dioxide) | 30%-35% | It helps to form a stable mineral phase structure, improve the strength and wear resistance of the brick, and ensure the integrity of the brick body under high temperature and mechanical stress. |

| Other impurities (such as Fe₂O₃, TiO₂, etc.) | A small amount | A moderate amount of impurity elements can affect certain properties of the brick to a certain extent. For example, a small amount of iron oxide may affect the color and some physical properties of the brick, but the overall content needs to be strictly controlled to ensure that the quality and performance of the product meet the requirements of cement kiln use. |

Send inquiry

Please Leave your message you want to know! We will respond to your inquiry within 24 hours!