Product detail

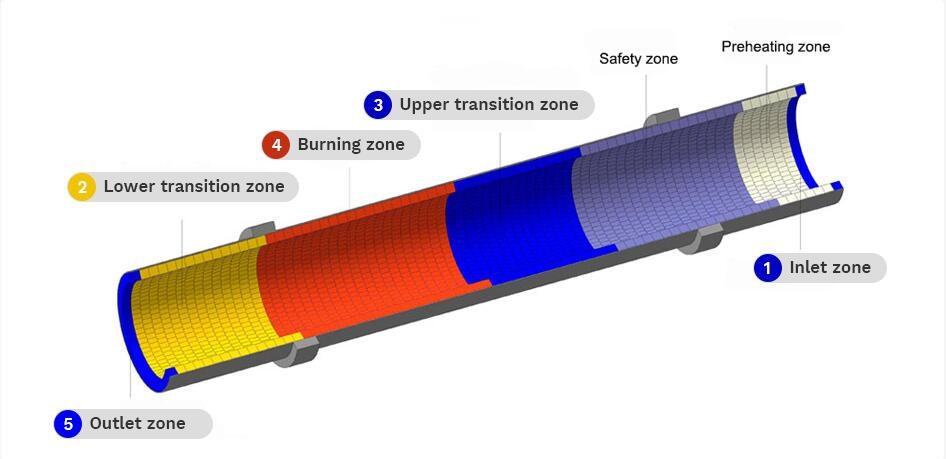

Zircon bricks for cement kiln

Product Overview

Zircon brick is a refractory material with excellent performance. With its excellent high temperature resistance, corrosion resistance and good mechanical strength, it plays a key role in many high-temperature industrial fields and has become an important cornerstone for ensuring the stable operation of the production process.

Product Application

Steel and Metallurgical Industry

In the steelmaking process, zircon bricks are widely used in the lining of steelmaking furnaces, such as converters and electric furnaces. Faced with the high temperature scouring of molten steel and the chemical erosion of slag, zircon bricks can effectively resist with their high melting point and chemical stability, extend the life of the furnace lining, reduce the production cost and downtime caused by frequent replacement of the furnace lining, and ensure the continuity of steelmaking operations.

Glass Manufacturing Industry

The temperature inside the glass melting furnace is extremely high and the working conditions are complex. Zircon bricks, as furnace lining materials, can withstand long-term immersion and erosion of glass liquid, maintain the structural integrity of the furnace, and ensure uniform heat distribution during the glass melting process, which helps to improve the quality and production efficiency of glass products and reduce glass defects and production interruptions caused by furnace lining damage.

Non-ferrous metal smelting field

When smelting non-ferrous metals such as copper and aluminum, the reaction temperature is high and highly corrosive media are generated. Zircon bricks are used in key parts such as melting furnaces and refining furnaces to create a stable high-temperature environment for the purification and refining of non-ferrous metals, prevent chemical reactions between furnace materials and metals or their compounds, ensure that the purity of non-ferrous metal products meets the standards, and improve the smelting recovery rate.

Ceramic firing industry

In kilns for firing high-end ceramics, zircon bricks are used to construct kiln walls, kiln roofs and other parts. Its uniform thermal conductivity stabilizes the temperature field in the kiln, allows the ceramic body to be heated evenly, reduces deformation, cracking and other defects caused by temperature differences, and helps the birth of high-quality ceramic products to meet the needs of artistic creation and high-end markets.

Product Parameters

| Ingredients | Content range (usually) | Function |

| Zircon (ZrSiO₄) | 60% – 80% | As the main mineral component, it provides high melting point (about 2500℃) characteristics, is the core guarantee of high temperature resistance and corrosion resistance, and lays the foundation for the basic performance of the brick. |

| Alumina (Al₂O₃) | 10% – 20% | It enhances the mechanical strength of the brick, improves the thermal shock resistance, makes it less likely to crack when the temperature changes sharply, and cooperates with zircon to cope with complex working conditions. |

| Silicon dioxide (SiO₂) | 5% – 15% | It fills in the gaps between mineral particles, optimizes the brick structure, promotes sintering, improves the overall density, and enhances the ability to block corrosive media. |

| A small amount of additives (such as TiO₂, CaO, etc.) | 1% – 5% | Added according to specific production needs, TiO₂ can improve sintering performance, and CaO helps to adjust the chemical activity of the brick and fine-tune product performance to adapt to special working conditions. |

Send inquiry

Please Leave your message you want to know! We will respond to your inquiry within 24 hours!