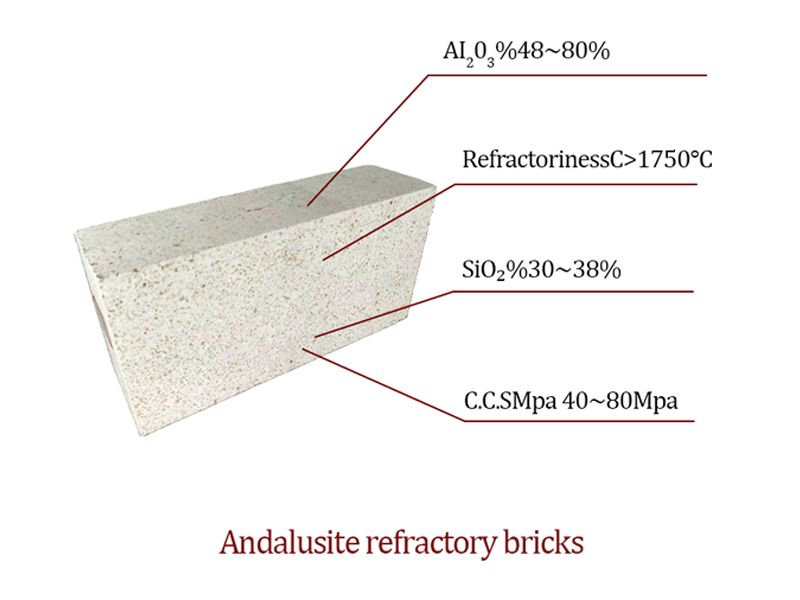

Product detail

Zircon Block

Composition: Al2O3

Application:Glass Kiln, incinerator

ZrO2:15-65%

Main Raw Material:Zircon sand and mullite or corundum

Size:As your requirements

Max Working Temperature:At least 1650℃

Product Introduction

Zircon bricks are made of zirconia and zirconia corundum cement as raw materials, mixed with rubber, molded, dried, and fired in a shuttle kiln at high temperatures.

Features

1.High molecular structure density.

2.High bulk density.

3.Good thermal shock stability.

4.Alkali and corrosion resistance.

Application

Zircon bricks are mainly used in alkali glass, borosilicate glass pool kiln bottom, upper space brick, brick hook, gap brick, flow slot brick, thermocouple brick and observation hole brick and other parts.

Product Parameters

| Item | ZS-G | ZS-Z | ZS-65A | ZS-65B | ZS-63 |

| ZrO2(%) | >=65 | >=68 | >=65 | >=65 | >=63 |

| SiO2(%) | <=33 | <=30 | <=33 | <=33 | <=35 |

| Fe2O3(%) | >=0.2 | >=0.2 | >=0.2 | >=0.2 | >=0.2 |

| TiO2(%) | <=1.2 | <=1.2 | <=1.2 | <=1.2 | — |

| Apparent Porosity(%) | <=10 | <=11 | <=17 | <=19 | <=20 |

| Bulk Density( g/cm3) | >=4.30 | >=4.10 | >=3.70 | >=3.60 | >=3.55 |

| Cold Crushing Strength(Mpa) | >=300 | >=200 | >=100 | >=80 | >=60 |

| Refractoriness Under Load ( 0.2MPa,0.6%) (℃) | >=1700 | >=1700 | >=1680 | >=1650 | >=1600 |

Send inquiry

Please Leave your message you want to know! We will respond to your inquiry within 24 hours!