News detail

What are the application principles of refractory materials?

The application principles of refractory materials are mainly based on their unique physical and chemical properties, which enable refractory materials to maintain structural integrity and chemical stability at high temperatures and harsh environments. The following are the main application principles of refractory materials:

High melting point and thermal stability

Refractory materials have a high melting point and can maintain structural integrity at high temperatures. At the same time, they also have good thermal stability and can resist thermal expansion and thermal shock damage at high temperatures. This high melting point and thermal stability enable refractory materials to withstand extreme high temperature environments and maintain the stability of their physical and chemical properties.

Acid and alkali erosion resistance

The main components of refractory materials are usually oxides, which have good acid and alkali erosion resistance. Therefore, refractory materials are widely used in the chemical industry, such as acid and alkali storage tanks and reactors in processes such as fertilizer manufacturing and metal smelting.

Redox properties

Some refractory materials have good redox properties. For example, metals such as aluminum and iron can undergo oxidation reactions with oxygen to form a stable oxide film at high temperatures, thereby improving the refractory properties of refractory materials. This redox property enables the refractory material to react with oxidizing gases such as oxygen at high temperatures to form a protective layer, further extending its service life.

Flame retardant properties

Organic refractory materials have good flame retardant properties, which can inhibit the combustion process and reduce the spread of flames. This property makes organic refractory materials widely used in the construction industry, such as for the manufacture of fire doors and fireproof panels. These materials can effectively prevent the spread of fire and protect the safety of personnel and property when a fire occurs.

Thermal decomposition and carbonization properties

Organic refractory materials have a high thermal decomposition temperature at high temperatures, which can prevent the spread of flames. At the same time, they also have low smoke generation and reduce the release of harmful substances. In addition, some organic refractory materials can undergo carbonization reaction at high temperatures to form a dense carbon layer. This carbon layer can block heat conduction and the spread of flames, further improving the fire resistance of the material.

Wide range of application fields

Based on the above principles, refractory materials are widely used in many fields. For example:

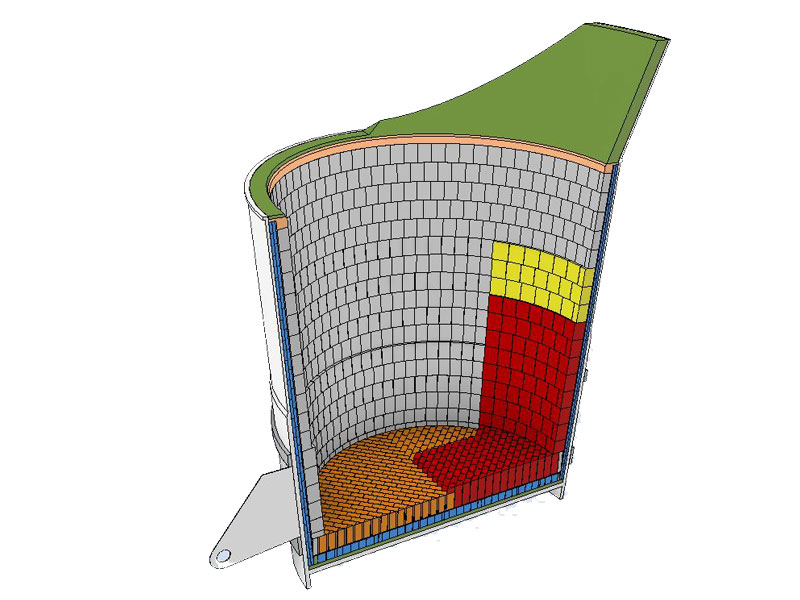

Steel industry: blast furnaces, converters, electric furnaces and other key equipment all use a large number of refractory materials as linings to withstand the erosion and scouring of high-temperature molten iron and steel.

Cement industry: Refractory materials are used for the lining of equipment such as cement kilns and coal mills. These equipment need to withstand high temperatures and wear during the production process, and refractory materials can provide good protection.

Glass industry: Refractory materials are widely used in glass melting furnaces. High temperature environments and chemical corrosion of glass liquids have high requirements for materials, and refractory materials can meet these requirements.

Chemical industry: Refractory materials are used to resist chemical erosion, such as acid and alkali storage tanks and reactors.

Aerospace: The application of refractory materials in the aerospace field includes rocket engines and thermal protection systems for spacecraft. These materials enable spacecraft to withstand the high heat flow of reentry into the Earth’s atmosphere.

In summary, the application principles of refractory materials mainly include high melting point and thermal stability, acid and alkali corrosion resistance, oxidation-reduction performance, flame retardancy, thermal decomposition performance and carbonization performance. These properties enable refractory materials to maintain structural integrity and chemical stability under high temperatures and harsh environments, making them an indispensable basic material in many fields.

Send inquiry

Please Leave your message you want to know! We will respond to your inquiry within 24 hours!