Product detail

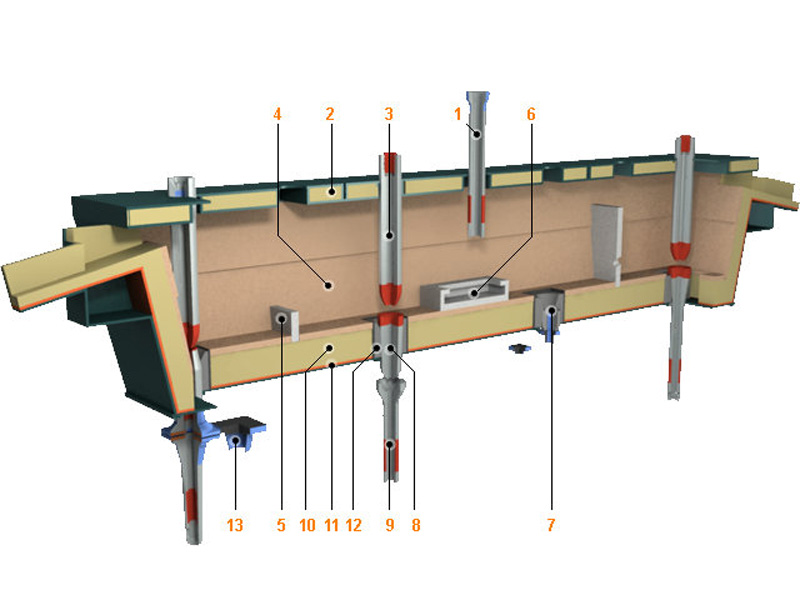

Tundish Refractories

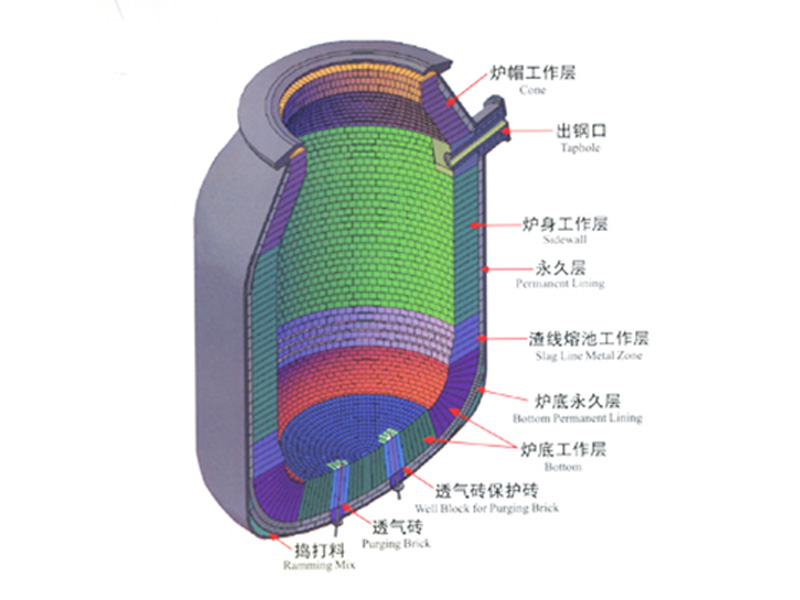

Materials for tundish

Insulation layer: asbestos board, isolation brick, low dense castable

Permanent layer: Castable, high alumina & mullite castable

Working layer: clay brick, high alumina brick & magnesia brick

1. Ladle shroud

2. Lid insulation

3. Stopper mono block

4. Bottom

5. Weirs and dams

6. Impact plate

7. Nozzle

8. Nozzle

9. Submerged shroud

10. Monolithic safety lining

11. Tundish insulation

12. Well block

13. Blank plate

Refractory for continuous casting

Product Parameters

Refractory for continuous casting

| Items 项目 | LZ-1 | LZ-2 | LZ-3 | LZ-4 | LZ-5 | LZ-6 |

| Material材质 | Magnesium-chrome paint | Magnesium paint | Magnesium calcium paint | High aluminum brick | High aluminum castable | Clay brick |

| Application 使用部位 |

Working layer | Working layer | Working layer | Working layer | Working layer | Permanent layer |

| Al2O3 % | 75 | ≥60 | >40 | |||

| Cr2O3 % | 5~10 | |||||

| MgO % | ≥70 | ≥85 | ≥70 | |||

| CaO % | ≥10 | ≤0.7 | ||||

| SiO2 % | ≤4 | ≤6 | ≤6 | |||

| Apparent porosity 显气孔率(%) |

19~21 | <18 | ||||

| Igloss灼减(%) | ≤3 | ≤3 | ||||

| Bulk Density 体积密度/g·cm3 (110°C, 24h) |

≥2.2 | ≥2.2 | ≥1.8 | ≥2.5 | ≥2.55 | ≥2.2 |

| (PLC)Permanent linear change on reheating 重烧线变化/% (1500°C, 3h) |

0~-1.5 | 0~-2.0 | 0~-3.5 | -0.2 | ±0.5 | |

| Thermal conductivity 热导率/W·(m·K)-1 (500°C) |

1.2 | ≤1.0 | ≤0.8 | |||

| Cold Crushing Strength 耐压强度/MPa (110°C, 24h) |

≥4 | ≥5 | ≥3 | ≥60 | ≥14.7 | ≥40 |

| Refractoriness 耐火度/°C |

>1790 | >1790 | ||||

| (RUL)Refractoriness Under Load 荷重软化温度/°C |

T1>1500 |

Send inquiry

Please Leave your message you want to know! We will respond to your inquiry within 24 hours!