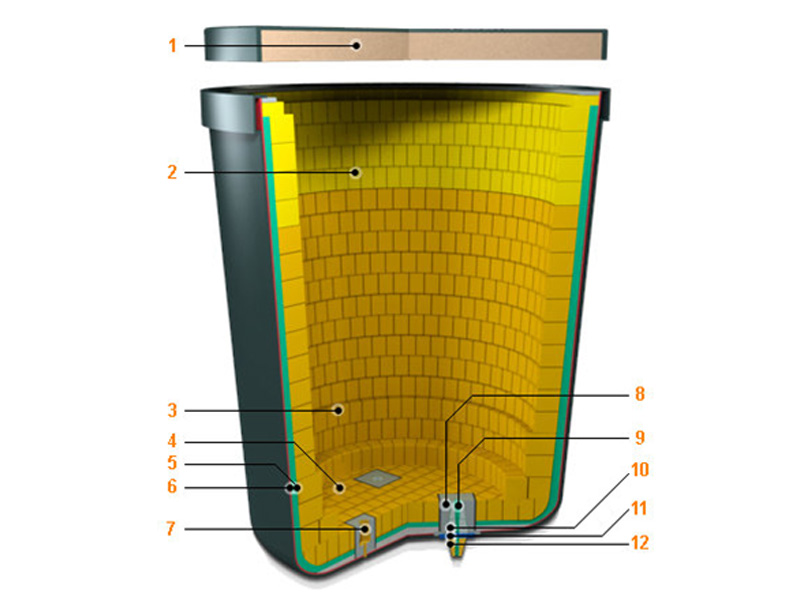

Product detail

Stopper Refractory Sleeve Brick

Introduction

1.Made by bauxite clinker and binder through Crushing,Mixing,Shaping,Drying and high temperature Sintering.

2.Al2O3 content is 48%-80%.

3.Main mineral components are corundum and mullite phases.

4.Refractoriness is usually above 1770℃,refractoriness under load is 1420-1550℃.It is a neutral refractory material so that it enjoys excellent resistance to acid and alkali corrosion.

5.Working temperature:1350℃ -1650℃.

Feature

1.High-temperature endurable;

2.Good thermal shock resistance;

3.High cold crushing strength;

4.Good resistance to abrasion and corrosion;

5.Good thermal spalling resistance;

6.High mechanical strength;

7.Good volume stability at high temperature;

Product Parameters

| Item | Index | ||||

| International code name | SK35 | SK36 | SK37 | SK38 | SK40 |

| Al2O3 % | >=48 | >=55 | >=65 | >=75 | >=80 |

| Fe2O3 % | <=2 | <=2 | <=2 | <=2 | <=2 |

| Refractoriness ℃ | >=1750 | >=1770 | >=1790 | >=1790 | >=1790 |

| Apparent porosity % | <=22 | <=22 | <=23 | <=23 | <=21 |

| Cold crushing strength Mpa | >=39 | >=44 | >=49 | >=54 | >=65 |

| Refractoriness under load(0.2MPa) ℃ | >=1420 | >=1470 | >=1500 | >=1520 | >=1530 |

| Reheating Linear Change (1500℃ 2h) % | +0.1~ -0.4

*1450℃ |

+0.1~ -0.4 | +0.1~ -0.4 | +0.1~ -0.4 | +0.1~ -0.4 |

Send inquiry

Please Leave your message you want to know! We will respond to your inquiry within 24 hours!