Product detail

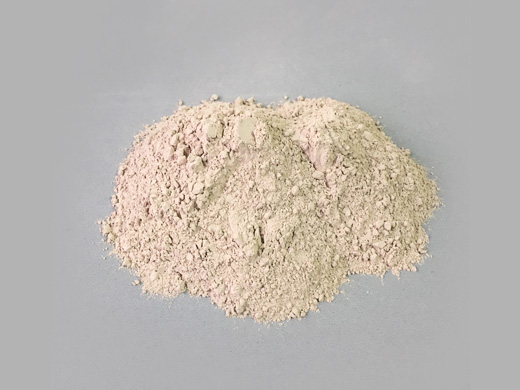

Slag Fluxing & Insulating Agent

Main Composition:SiO2 + CaO

Application:Metallurgical industry

Capacity:1000 tons per month

Package:Export ton bag

Size:As your requirements

Product Introduction

In order to solve the serious problem that the steel slag in ladle is much and sticky in the process of “furnace protection by slag splashing” in converter, we develop this product exclusively.

Features

1.Excellent ability to flux steel slag.

2.Good thermal insulation.

3.Adsorbing inclusions and other comprehensive properties.

Application

Used by many metallurgical enterprises, this product is recognized by good slag fluxing ability and thermal insulation performance.It can be added directly to the surface of molten steel in ladle according to the adding amount of 0.7 to 1.2 kg per ton of steel.

Product Parameters

Slag Fluxing & Insulating Agent for Ladle

| Melting Point(℃) | Melting Speed(S) | Expansion Ratio | CaO% | SiO2% | Al2O3% | C% | H2O% |

| 1050-1260 | 60-120 | ≥1.5 | 15-25 | 15-30 | 6-14 | 15-20 | ≤0.75 |

Slag Fluxing & Insulating Agent for Molten IronChemical Composition:

| Item | SiO2% | CaO% | Fe2O3% | Al2O3% | MgO% | C% |

| 38-48 | 10-20 | ≤3 | ≤8 | 6-10 | 28-38 |

Physical Properties:

| Item | H2O | Particle Size (mm) | Melting Point | Volume | Expansion Ratio |

| Index | <1% | 0.15-2mm | 1250-1350℃ | ≤7 | ≤7 |

Send inquiry

Please Leave your message you want to know! We will respond to your inquiry within 24 hours!