Product detail

Sintered zirconium brick

Product introduction

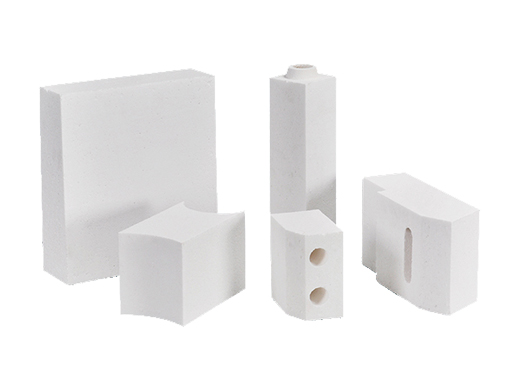

Sintered zirconium brick is a kind of advanced refractory material made of zirconium oxide (ZrO₂) as the main raw material and sintered at high temperature. It has a series of excellent properties, such as high melting point, high hardness, good chemical stability, thermal shock resistance and low thermal conductivity. Its appearance is usually a regular block, and the color is mostly white or slightly yellowish. Depending on the different production processes and additives, there may be some slight color differences. The size and shape of sintered zirconium bricks can be customized according to specific usage requirements. Common ones include standard brick types and some special shapes of bricks to meet the masonry requirements of different kilns and equipment.

Application areas

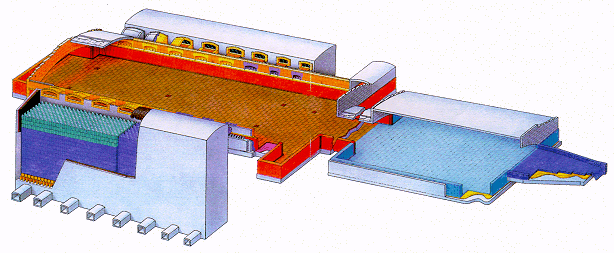

Glass industry: In glass melting furnaces, sintered zirconium bricks can be used in key parts, such as pool walls, flow holes, etc. It can resist the high temperature erosion and scouring of glass liquid, ensure the stable operation of glass melting furnaces, and improve the quality and output of glass.

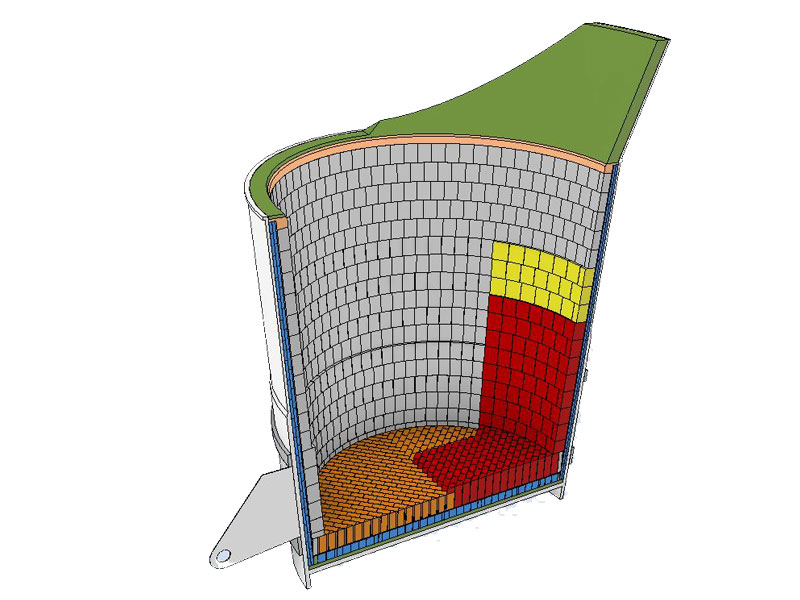

Ceramic industry: used for the lining of ceramic kilns, it can withstand the thermal stress and chemical erosion during high temperature firing, which helps to maintain the temperature uniformity in the kiln, improve the firing quality of ceramic products, and extend the service life of the kiln.

Metallurgical industry: Sintered zirconium bricks can be used as lining materials in non-ferrous metal smelting furnaces, ladles and other equipment. It can resist the erosion of high-temperature molten metal and slag, reduce heat loss, and improve smelting efficiency and equipment safety.

Other fields: It can also be used in high-temperature equipment in the electronics, chemical and other industries, such as electronic component sintering furnaces, chemical reactor linings, etc., to provide reliable refractory protection for these high-temperature process.

Product Parameters

| Composition | Content range | Function |

| ZrO₂ | Usually ≥90% | It is the main component of sintered zirconium bricks, giving the material high melting point, high hardness and good chemical stability. |

| SiO₂ | Usually <5% | It can improve the sintering performance of the material and the density of the product to a certain extent, but too high a content may reduce the high temperature performance of the material. |

| Al₂O₃ | Usually <3% | It can be used as an additive. Adding an appropriate amount helps to improve the thermal shock resistance and mechanical strength of the material. |

| CaO/MgO | Usually <2% | It is mainly used to stabilize the crystal form of zirconium oxide and improve the stability and thermal shock resistance of the material. |

Send inquiry

Please Leave your message you want to know! We will respond to your inquiry within 24 hours!