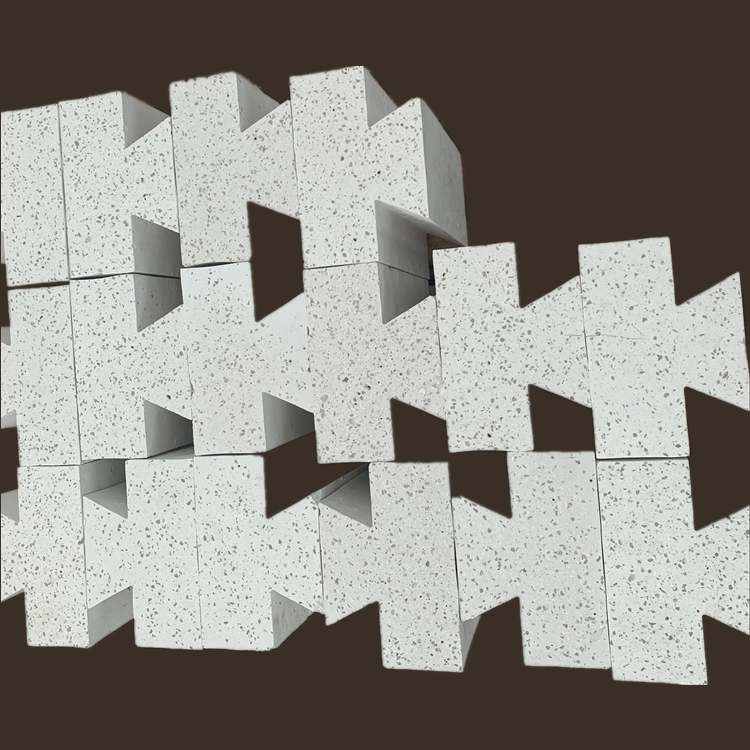

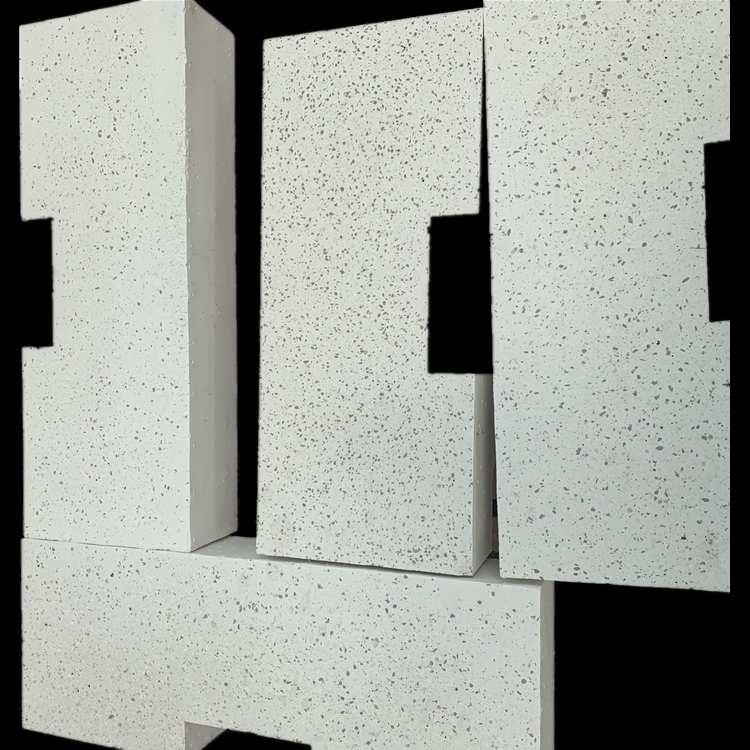

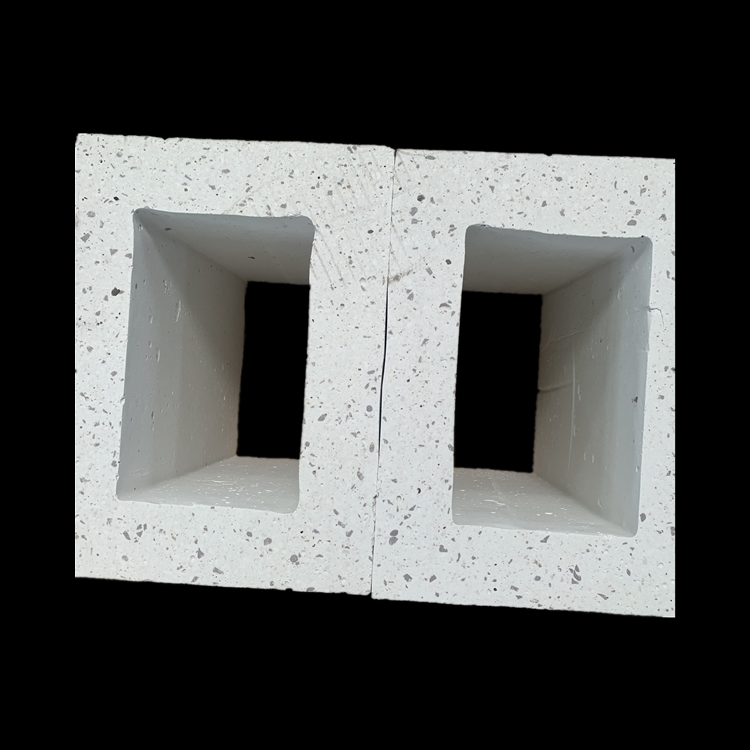

Product detail

Sillimanite Bricks

Sillimanite refractory brick is a refractory bricks made of sillimanite minerals. The sillimanite is calcined at high temperature and converted to mullite and free silica. Sillimanite refractory brick is generally used high temperature firing method and mud casting method. Its physical and chemical properties are better than high alumina bricks, refractoriness 1770 ~ 1830 ℃, load softening start point 1500 ~ 1650 ℃.

Application of Sillimanite refractory brick

Sillimanite fire bricks are currently mainly used in the tin bath roof tiles of float glass production lines in the flat glass industry. Because sillimanite refractories have good high-temperature thermal stability, they are resistant to erosion and erosion by molten glass, and have little pollution to molten glass. It is suitable for equipment such as forehearths, feeders, and pipe-drawing machines in the glass industry, which can significantly improve productivity. Products include channel bricks, flow troughs, rotating pipes, bowls, bowls, mixing slurry, punches, barrels, fire-stop slag bricks, gate bricks, front arch bricks, rear arch bricks, bowl cover, and openings Various varieties and specifications such as bricks, burning nozzle bricks, beams, and cover bricks.

Classification of Sillimanite fire brick

1. Classified by Al2O3 content in Sillimanite fire brick

Class Ⅰ Al2O3 content>65%

Class Ⅱ Al2O3 content is 60%

Class Ⅲ Al2O3 content is 55%.

Sillimanite fire brick have followed characteristics :

1.Sillimanite fire brick has high softening temperature under load

2.Sillimanite fire brick has thermal shock resistance

3.Sillimanite fire brick has chemical resistance, etc.

Production process of Sillimanite fire brick

The production process of Sillimanite fire brick includes crushing-mixing-forming-firing-packaging-shipping. It is a neutral refractory material made of bauxite or other raw materials with high oxide content through molding and calcination. High thermal shock stability, refractoriness above 1770℃. The slag resistance is better.

1. Screening and crushing of Sillimanite fire brick materials

The high alumina bauxite clinker is crushed into the required particles and fine powder by a jaw crusher and a dry mill

2. Sludge ratio and mixing of Sillimanite fire brick

Use mixing equipment for mixing: the order of addition is: pellets, pulp waste liquid, mixing for 2 to 3 minutes, then adding mixed fine powder, mixing for 8 to 10 minutes, and then discharging for use.

3. Forming: Forming with a hydraulic press

4. Firing of Sillimanite fire brick

Put the dry and flawless semi-finished products into a high-temperature electric furnace for firing. Operate in accordance with the operating procedures of the electric furnace. The firing temperature is 1500℃, and the firing cycle is 6h.

Packaging Details

1.On wooden pallets with plastic cover

2.According to customer’s demands

Product Parameters

| Iterm | Indicators | |||

| Al2O3% | >= | 65 | 60 | 55 |

| Fe2O3% | <= | 1.0 | 1.0 | 1.5 |

| SiO2% | <= | 32 | 37 | 42 |

| Bulk Density (g/cm3) | >= | 2.5 | 2.35 | 2.3 |

| Apparent Porosity % | <= | 18 | 19 | 20 |

| Cold Crushing Strength (Mpa) | >= | 60 | 60 | 50 |

| Refractoriness under Load 0.2Mpa (℃) | >= | 1650 | 1600 | 1580 |

Send inquiry

Please Leave your message you want to know! We will respond to your inquiry within 24 hours!