Product detail

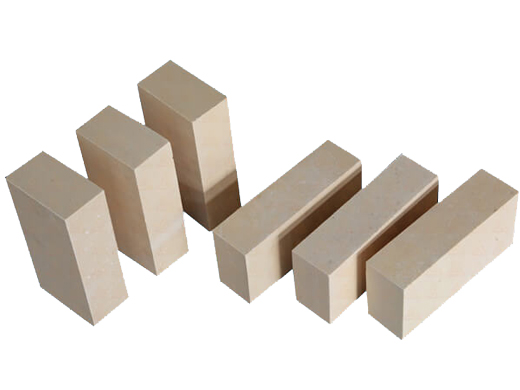

SiC Mullite Brick

Composition:SiC + Al2O3

Application:Cement and Lime Kiln, or other industrial kilns.

Al2O3:60-65%

Color:Brown

Size:As your requirements

Raw Material:Silicon carbide and mullite

Refractoriness:≥1790℃

Package:Wooden pallets and polyboard

Product Introduction

Mullite silica bricks are made of high-alumina bauxite clinker and silicon carbide through high-pressure molding and high-temperature firing.

Features

1.Good high temperature structural strength.

2.Good thermal shock stability.

3.Good abrasion resistance and strong peel resistance.

4.Good volume stability under high temperature.

5.High Cold Crushing Strength.

Application

Mullite silica brick is suitable for transition zone, cooling zone, kiln mouth and other locations of cement kiln.

Product Parameters

| Item | Silicon Mullite Wear-resistant Brick | |||

| AZM-1 550 | AZM-1650 | AZM-1680 | ||

| Chemical Composition(%) | SiC+SiO2 | >=35 | >=30 | >=32 |

| Al2O3 | >=60 | >=65 | >=65 | |

| Volume Density(g/cm3) | >=2.55 | >=2.65 | >=2.70 | |

| Apparent Porosity(%) | <=20 | <=19 | <=19 | |

| Cold Crushing Strength(Mpa) | >=80 | >=90 | >=100 | |

| Refractoriness Under Load(T0.6,℃) | >=1550 | >=1650 | >=1680 | |

| Thermal Shock Resistance,Cycles(1100℃,Water-cooling) | >=10 | >=15 | >=20 | |

Send inquiry

Please Leave your message you want to know! We will respond to your inquiry within 24 hours!