Product detail

Silica-Mullite Brick for Cement Kiln

Product Overview

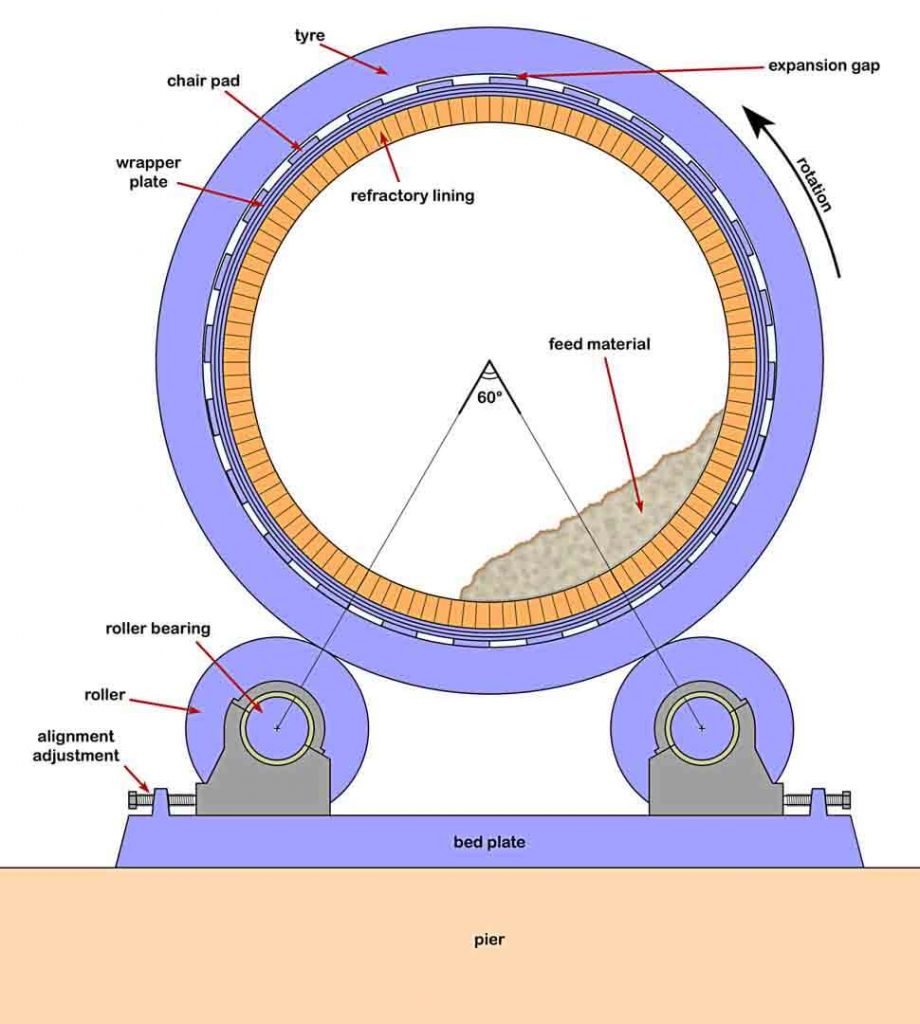

Silica-Mullite Brick is a high-performance refractory material specially developed for the working conditions of cement kilns. It combines the characteristics of a variety of high-quality raw materials, and exhibits excellent performance in harsh environments such as high temperature and strong erosion in cement kilns, providing reliable guarantees for the stable operation of cement kilns.

Product Performance

High refractoriness: Silica-Mullite Brick has a high refractoriness and can withstand high temperatures of up to about 1600℃ in cement kilns. It is not easy to soften and deform under long-term high temperature environments, ensuring the stability of the kiln structure.

Good thermal shock resistance: Cement kilns frequently experience drastic changes in temperature during operation. Silica-MulliteBrick has good thermal shock resistance due to its special material structure. It can effectively resist the thermal stress caused by sudden temperature changes, reduce the generation and expansion of cracks, and extend the service life.

Excellent corrosion resistance: There are various corrosive media such as alkaline substances and molten materials in cement kilns. Silica-MulliteBrick has a strong resistance to these corrosions. Its dense structure and stable chemical composition can effectively prevent the penetration of corrosive media and maintain the integrity of the brick body.

Application scenarios

Cement kiln firing zone: This area is the part with the highest temperature and the worst working conditions in the cement kiln. The high refractoriness, corrosion resistance and thermal shock resistance of silica-Mullite bricks make them ideal lining materials for the firing zone. They can withstand the erosion of high-temperature flames and the chemical erosion of clinker, reduce the frequency of kiln lining replacement, and improve production efficiency.

Transition zone: The transition zone is between the firing zone and the cooling zone, with large temperature changes and certain corrosiveness. The good comprehensive performance of silica-Mullite bricks can adapt to the complex working conditions in this area and effectively reduce the risk of damage caused by temperature fluctuations and erosion.

Product Parameters

| Ingredients | Content (%) | Function |

| SiO₂ | 50 – 60 | It is one of the main components of silica-mullite bricks, which gives the bricks a certain degree of fire resistance and chemical stability. At the same time, it can form a stable liquid phase at high temperature to promote the sintering and densification of the bricks. |

| Al₂O₃ | 25 – 35 | It improves the refractoriness and mechanical strength of the bricks and enhances their corrosion resistance. It interacts with SiO₂ and other components to form a mullite phase and improve the performance of the bricks. |

| Mullite | 15 – 25 | Mullite is the key crystal phase of silica-mullite bricks. It has high hardness, high strength and good thermal shock resistance, and plays an important role in improving the comprehensive performance of the bricks. |

| Other additives (such as flux, etc.) | Appropriate amount | It regulates the sintering temperature and performance of the bricks, promotes the reaction and combination between the components, and optimizes the microstructure of the bricks. |

Send inquiry

Please Leave your message you want to know! We will respond to your inquiry within 24 hours!