Product detail

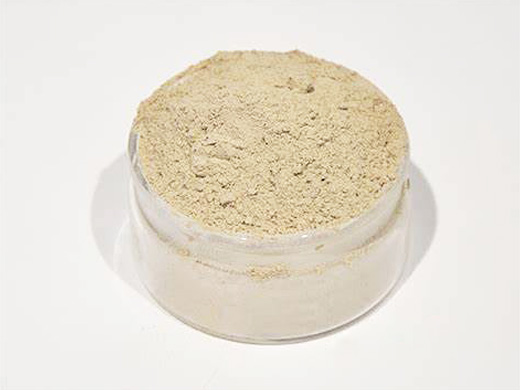

Silica Mortar

Main Composition:SiO2

Application:Coke oven, etc

Capacity:3000 MT per month

Color:Grey

Raw Material:Quartz sand

Product Introduction

Silica mortar is also known as joint filler. It is made of silica powder and by a ratio of SiO2 powder. The binder is normally made of clay or additive.

Features

1.High adhesive strength.

2.High refractoriness.

3.Superior installation performance.

Application

Silica mortar is mainly used for laying and repair of coke oven, hot blast stove, glass furnace and other masonry of high quality silica bricks industrial furnace.

Product Parameters

| Item | Silica Mortar | |||

| RGN-94 | JGN-92 | BGN-96 | GGN-94 | |

| SiO2 (%) | >=94 | >=92 | >=96 | >=94 |

| Cold Rupture Bonding StrengthAfter Drying 110℃ (Mpa) | 1.0 | 1.0 | 0.8 | 0.5 |

| Cold Rupture Bonding StrengthAfter Firing 1400℃*3h (Mpa) | 3.0 | 3.0 | 0.5 | 1.5 |

| Refractoriness Under Load (0.2MPa) | 1600 | 1500 | 1620 | — |

| Grain Composition +0.5mm (%) | <=1.0 | <=3.0 | <=2.0 | <=3.0 |

| Grain Composition -0.074mm (%) | 60 | 50 | 60 | 50 |

| Bonding Time (min) | 1-2 | 1-2 | 2-3 | 1-2 |

| CN/ Refractoriness(Cone) | 170 | 166 | 172 | 170 |

Send inquiry

Please Leave your message you want to know! We will respond to your inquiry within 24 hours!