Product detail

Silica clay bricks for cement kiln

Product Introduction

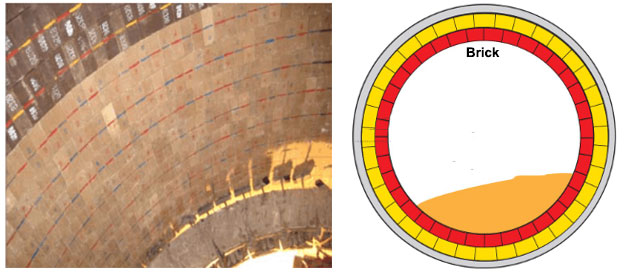

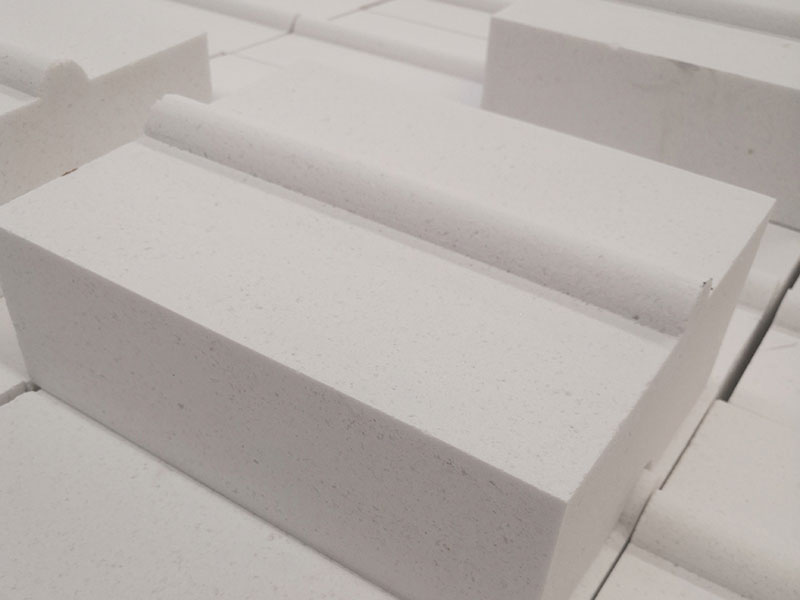

Siliceous clay bricks for cement kilns are high-quality refractory materials. They possess excellent resistance to high temperatures, thermal shock, and chemical erosion, making them suitable for the harsh environment inside cement kilns. These bricks are carefully manufactured to ensure consistent quality and performance, with a dense structure that helps to maintain the integrity of the kiln lining and prolong its service life.

Application

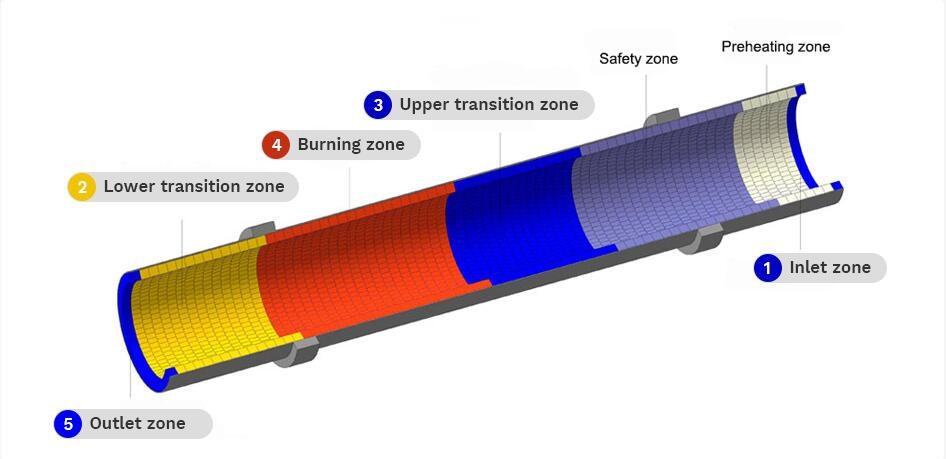

These bricks are widely used in various parts of cement kilns, such as the preheating zone, calcining zone, and cooling zone. They play a crucial role in withstanding the high temperatures and corrosive gases generated during the cement production process, protecting the kiln shell and ensuring the stable operation of the kiln. By using siliceous clay bricks, cement manufacturers can improve the efficiency and reliability of their production lines, reducing maintenance costs and downtime.

Product Parameters

| Parameter | Value |

| Alumina Content (%) | 20 – 30 |

| Silica Content (%) | 60 – 70 |

| Apparent Porosity (%) | 18 – 25 |

| Bulk Density (g/cm³) | 2.1 – 2.3 |

| Cold Crushing Strength (MPa) | 40 – 60 |

| Refractoriness (℃) | 1650 – 1700 |

Send inquiry

Please Leave your message you want to know! We will respond to your inquiry within 24 hours!