News detail

Selection of refractory materials for grate cooler and kiln door cover

In the cement industry, the process methods used to produce cement have undergone a series of qualitative and quantitative changes with the changes in the kilns used, which has promoted the rapid development of the entire industry. Cement kilns have experienced several stages of development, from vertical kilns to mechanical vertical kilns to wet rotary kilns to new dry rotary kilns. Dry production of cement is currently the most mature and stable cement production process. With the development of the cement industry, the clinker output of dry rotary kilns has gradually developed from 2,000 tons, 3,000 tons, 4,000 tons, and 5,000 tons per day in the early days to 10,000-14,000 tons per day. In addition, with the requirements of national environmental protection policies, the use of dry cement kilns to coordinate the disposal of garbage and hazardous waste has become an industry trend. However, while the use of cement kilns to coordinate the disposal of hazardous waste has developed rapidly, the working conditions of cement kilns have shown a deteriorating trend, exacerbating the damage of refractory materials used in cement kilns.

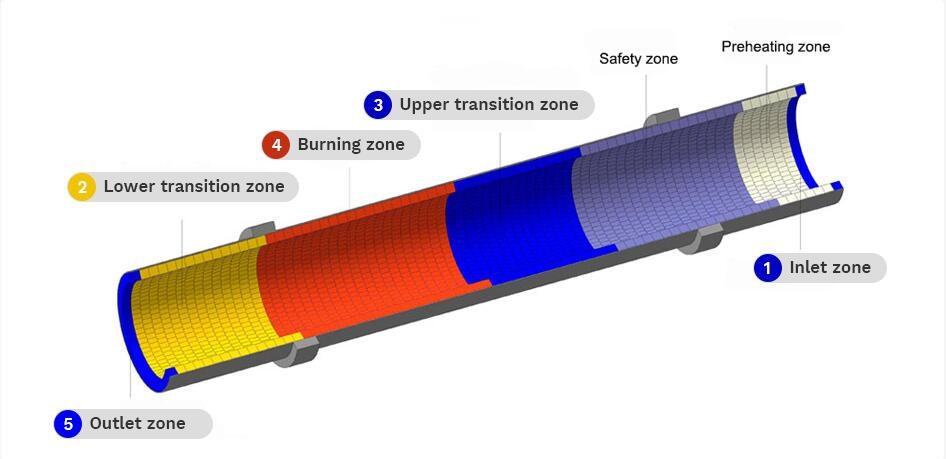

The new dry process cement production line is mainly composed of several systems, including preheater, decomposition furnace, rotary kiln, grate cooler, and tertiary air duct. Each area has different working characteristics and use environment. Due to the process characteristics, the new dry process rotary kiln causes the enrichment of volatile components such as alkali and sulfur, the increase of kiln temperature, the increase of kiln diameter, the acceleration of kiln speed, and the complex structure. The comprehensive crushing effect of chemical erosion, high temperature damage, mechanical stress and thermal stress on refractory materials is greater than that of traditional kilns. In addition, the current higher environmental protection and energy-saving requirements should be given. Different refractory materials should be selected in each area according to the working conditions.

Common uses of rotary kilns:

Clinker production: In the cement production process, the raw material mixture is put into the rotary kiln and clinker is produced by high-temperature calcination.

Limestone slow burning: Rotary kilns are also used in the limestone burning process to convert limestone into lime. Lime is an important raw material in many industrial and agricultural applications, such as cement production, steel smelting, etc.

Metallurgical industry: Rotary kilns are used in the metallurgical industry for the reduction and purification of ores.

Chemical reaction: Rotary kilns are widely used in various chemical reactions, such as catalyst burning in the process of oil refining, pyrolysis and incineration in the treatment of solid waste, etc.

Waste treatment: Rotary kilns can be used to treat various wastes, such as urban garbage, industrial waste, medical waste, etc., and waste can be treated and converted into energy or harmless substances.

The production characteristics of rotary kilns are that the masonry of the kiln rotates with the kiln shell at high temperature, is in a state of vibration for a long time, and is also subject to the wear and impact of the furnace charge. Therefore, the bricks used for kiln lining should have high strength and low porosity, the brick joints of the masonry should be tight and the staggered joints should be uniform, and the strength of the mud should be high to ensure that the masonry is firm and reliable.

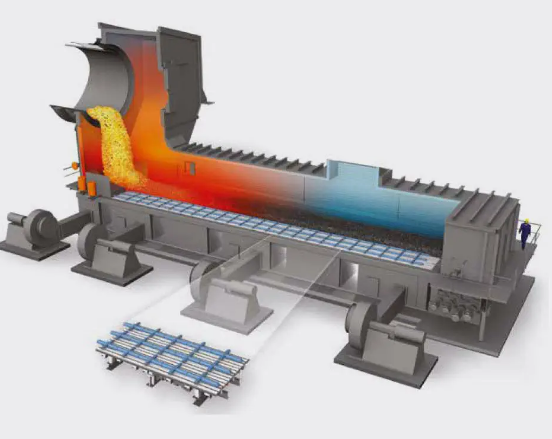

The refractory materials at the discharge port of the grate cooler must withstand the wear of the hot materials out of the kiln and the strong hot air flow, and the construction surface in the grate cooler area is very irregular and cannot be built with refractory bricks, so it can only be cast with castables for overall casting construction.

The kiln door cover is a masonry structure that seals the grate cooler. It is used to prevent the heat loss from the grate cooler and rotary kiln, collect the hot air and transport it into the preheater through the tertiary air duct. The kiln door cover mainly bears the scouring effect of high-temperature gas. Due to its irregular shape, it is mostly built with high-aluminum castables or steel fiber castables. At the connection position with the tertiary air duct, due to the high wind speed, the hot air containing clinker particles will cause serious wear to the area, so it is built with high-wear-resistant castables. In order to reduce heat loss, before the construction of the grate cooler and kiln door cover castables, a layer of calcium silicate board must be pasted after welding the anchors, and then a layer of waterproofing agent must be applied, and finally the castables must be poured inside for construction.

Send inquiry

Please Leave your message you want to know! We will respond to your inquiry within 24 hours!