Product detail

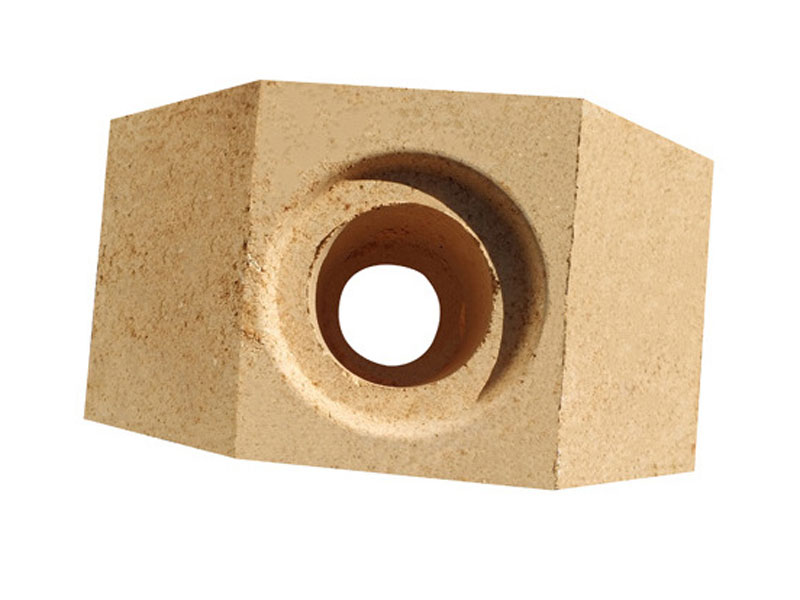

Runner Block

Bottom pouring bricks runner bricks are hollow refractory bricks that are built in the groove of the bottom plate for ingot casting and connect the sub-steel bricks and steel ingot moulds, commonly known as soup bricks. The products are generally cuboid hollow clay bricks with various specifications. In order to reduce the resistance during the flow of molten steel and prevent leakage of steel, it is required that the inner hole of the flowing steel brick is smooth, the shape is regular, and the joints are tight.

It is applied to flat cast steel of various steel types (including stainless steel and various alloy steels). The product has high refractoriness, good crack resistance and strong corrosion resistance. Regular shape, smooth flow, accurate size, complete varieties.

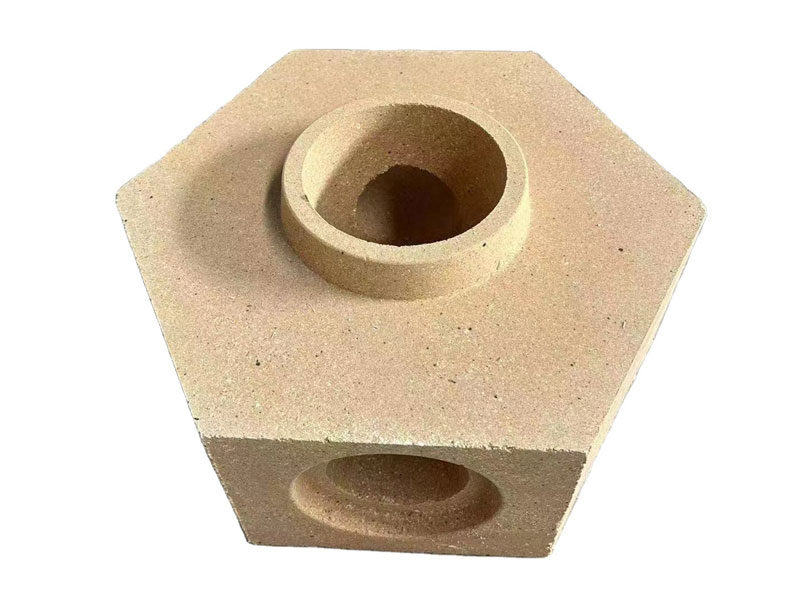

Henan Hongtai Kiln refractory offer a complete range of high quality dry pressed Bottom Pouring Refractory Brick , ranging from 42% to 75% in alumina content. included Sleeve Brick, Runner Bricks ,End Runner brick with riser , Bottom Guide ,Central Brick(Spider) , Funel , Round and Square Tube, Tail brick ,well block , stopper etc …

Usage: The worldwide percentage of steel and alloy produced via ingot casting and bottom pouring has decreased since decades. However some steel and alloy applications will continue to be bottom poured in the foreseeable future.

This includes steel and alloy ingots for intermediate and large forgings for the transportation, oil, heavy equipment and aeronautical industries. Vacuum remelt electrodes and specialty alloys such as nickel based, nickel cobalt, nickel copper and those alloys which can’t be economically continuously cast will continue to be ingot cast.

Product Parameters

Hollowware Brick

| Item | Unit | Bottom Pouring Brick | |||||||

| Fireclay | High Alumina | ||||||||

| 40 | 42 | 45 | 50 | 60 | 65 | 70 | 75 | ||

| Al2O3 | % | ≥40 | ≥42 | ≥45 | ≥50 | ≥60 | ≥65 | ≥70 | ≥75 |

| Fe2O3 | % | ≤2.5 | ≤2.2 | ≤2.2 | ≤2.2 | ≤2.2 | ≤2 | 2 | 2 |

| Bulk Density | g/cm3 | ≥2.10 | ≥2.15 | ≥2.17 | ≥2.20 | ≥2.25 | ≥2.25 | ≥2.30 | ≥2.35 |

| Apparent Porosity | % | ≤25 | ≤26 | ≤26 | ≤26 | ≤26 | ≤26 | ≤26 | ≤26 |

| Cold crushing strength | MPa | ≥30 | ≥35 | ≥35 | ≥35 | ≥35 | ≥35 | ≥40 | ≥40 |

| Refractoriness Under Load 0.2 MPa T0.5 | ºC | ≥1320 | ≥1350 | ≥1350 | ≥1400 | ≥1420 | ≥1450 | ≥1450 | ≥1500 |

| Usage | Cast Irons ,Low Alloy Steel | Low to medium alloy steel | |||||||

| Item | Unit | Bottom Pouring Brick | |||

| JA-60 | JA-70 | JM62 | JM70 | ||

| Main Raw Material | Andlusite | Andlusite | Mullite | Mullite | |

| Al2O3 | % | ≥60 | ≥70 | ≥62 | ≥70 |

| Fe2O3 | % | ≤2.00 | ≤1.80 | ≤1.50 | ≤1.80 |

| Bulk Density | g/cm3 | ≥2.25 | ≥2.30 | ≥2.30 | ≥2.32 |

| Apparent Porosity | % | ≤25 | ≤26 | ≤26 | ≤25 |

| Cold crushing strength | MPa | ≥35 | ≥40 | ≥35 | ≥40 |

| Refractoriness Under Load 0.2 MPa T0.5 | T0.5 /ºC | ≥1500 | ≥1550 | ≥1600 | ≥1620 |

| Refractoriness | ºC | ≥1500 | ≥1500 | ≥1760 | ≥1780 |

| heating permanent line change rate 1500ºC*24h | % | -0.1- +0.4 | -0.1- +0.4 | -0.1- +0.4 | -0.1- +0.4 |

| Usage | High Alloy Steel , long casting times | ||||

Dense Refractory Brick

| Item | Fireclay Brick | ||

| High Duty Fireclay Brick | Super Duty Fireclay Brick | High Fired ,Super Duty Fireclay Brick | |

| Al2O3 | ≥36 % | ≥42 % | ≥42.1 |

| Fe2O3 | ≤2.5% | ≤2.5% | ≤2.0 |

| Pyrometric Cone Equivalent Orton Standard Cones Temperature Equivalent | 32 | 34 1753ºC | 34 1753ºC |

| 1717ºC | |||

| Bulk Density | ≥2.15 | ≥2.20 | ≥2.29 |

| Apparent Porosity | 22-24% | 22-24% | 17-19% |

| Cold crushing strength | ≥25 | ≥35 | ≥42 |

| Hot Load Test Deformation at 1350ºC | 1% | -0.2 to -0.7% | ≥05-0.7% |

| Permanent Linear Change at 1400 ºC | 0% | 0% | 0% |

| Item | Unit | Special High Quality Fire Clay Brick | |||

| YUFENG-DN11 | YUFENG-DN14 | YUFENG-DN17 | |||

| Al2O3 | % | ≥47 | ≥45 | ≥42 | |

| Fe2O3 | % | ≤1.20 | ≤1.5 | ≤1.80 | |

| Bulk Density | g/cm3 | ≥2.40 | ≥2.34 | ≥2.26 | |

| Apparent Porosity | % | ≤11 | ≤14 | ≤17 | |

| Cold crushing strength | MPa | ≥80 | ≥65 | ≥50 | |

| Permanent Linear Change | 1400 ºCx 2h | % | – | +0.1 to -0.2% | +0.1 to -0.2% |

| 1500 ºCx 2h | +0.1 to -0.2% | – | – | ||

| Refractoriness Under Load 0.2 MPa T0.5 | T0.5 /ºC | ≥1520 | ≥1470 | ≥1430 | |

Send inquiry

Please Leave your message you want to know! We will respond to your inquiry within 24 hours!