Product detail

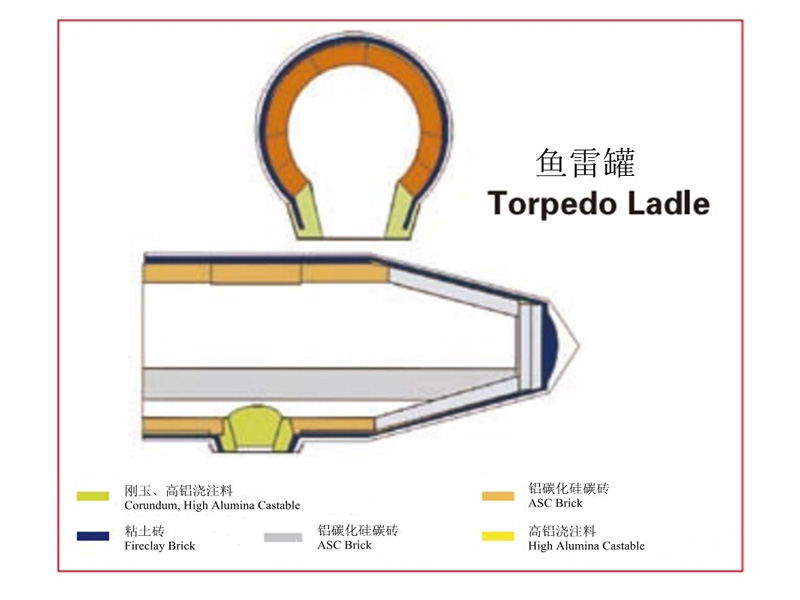

Refractories for Torpedo Ladle

Increased wear mechanisms caused by liquid metal treatments such as desulphurisation and thermal shock conditions restricts the usage of traditional lining concepts. These treatments lead to higher temperatures, higher slag turbulances and higher chemical attacks.

In order to provide higher service lifes, it is recommended to use ASC (Al2O3-SiC-C) bricks in torpedo ladles being no longer just a hot metal transfer car.

Product Parameters

| Item项目 | Al2O3-SiC-C Brick 铝碳化硅碳砖 |

||||||

| ASC-Z1 | ASC-T1 | ASC-D | ASC-Z2 | ASC-Z3 | ASC-T2 | ||

| Al2O3 (%) | ≥ | 55 | 57 | 62 | 65 | 70 | 65 |

| SiC (%) | ≥ | 17 | 14 | 10 | 10 | 7 | 7 |

| C (%) | ≥ | 8.0 | 6.0 | 4.0 | 10.0 | 10.0 | 9.0 |

| Apparent porosity 显气孔率 (%) |

≤ | 8 | 10 | 10 | 7 | 7 | 7 |

| Bulk density 密度 (g/cm3) |

≥ | 2.75 | 2.75 | 2.75 | 2.90 | 3 | 2.90 |

| Cold crushing strength 常温耐压强度(MPa ) |

≥ | 35 | 40 | 45 | 45 | 55 | 50 |

| Application 应用 |

渣线区 | 包壁、包底 | 顶部 | 渣线区 | 渣线区 | 包壁、包底 | |

| Slag zone | Side wall, bottom | Top | Slag zone | Slag zone | Side wall, bottom | ||

Send inquiry

Please Leave your message you want to know! We will respond to your inquiry within 24 hours!