Product detail

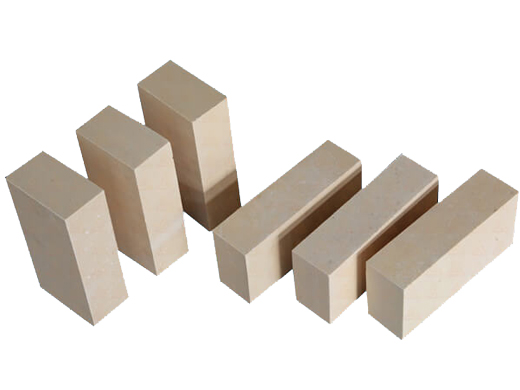

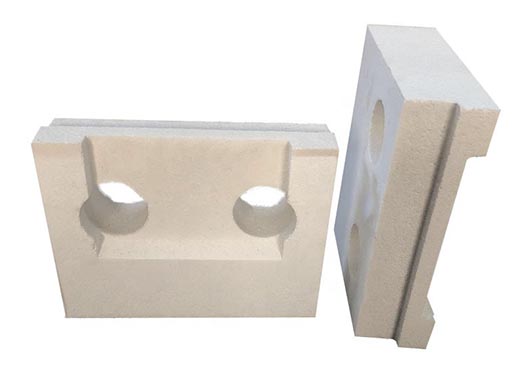

Phosphate bricks

Phosphate bricks are refractory materials made of high-alumina bauxite clinker and other materials as the main raw materials, and phosphoric acid or aluminum phosphate as the binder.

Production process: Usually, special or first-grade dense high-alumina bauxite clinker is used as the main raw material, phosphoric acid solution or aluminum phosphate solution is used as the binder, and it is made by semi-dry machine pressing and heat treatment at 400-600℃. Some materials with heating expansion such as kyanite and sillimanite will be added to prevent shrinkage at high temperatures.

Product characteristics

Advantages: It has high strength and good wear resistance, and can withstand the scouring and friction of materials. It has excellent chemical corrosion resistance, especially the alkali resistance is better than clay bricks and high-alumina bricks. It has good thermal shock resistance and can remain stable in an environment with rapid temperature changes.

Disadvantages: The load softening temperature of traditional phosphate bricks is low, generally around 1300℃, and the reburning line shrinks greatly. However, by improving the process and adding specific ingredients, high-load soft phosphate bricks with a load softening temperature of not less than 1550℃ have been developed.

Application fields

Cement industry: used in the preheating zone, high temperature zone and tuyere bricks of rotary kilns and vertical kilns for cement industry. It is also often used in the transition zone, kiln mouth, kiln door cover, cooler lining and other vulnerable parts of rotary kilns.

Lime industry: It is an ideal lining material for lime kilns. It can be used in the high temperature zone and transition zone of lime kilns. It is close to the atmosphere of lime lining and the burned lime is active.

Other industries: It is also used in zinc smelting kilns, carbon industry rotary kilns, electric furnace tops, ladles and other fields. With its wear resistance and slag erosion resistance, it can ensure the stable operation of equipment.

Product Parameters

| Ingredients | Description |

| High-alumina clinker | Provides high refractoriness and mechanical strength and is the main aggregate of phosphate bricks |

| Phosphoric acid or aluminum phosphate solution | As a binder, it can effectively promote the bonding between materials and improve the overall performance of the product. During use, phosphoric acid or aluminum phosphate will react physically and chemically with other components in the brick to form a binder mainly composed of quartz-type aluminum orthophosphate, which enhances the structural stability and high temperature resistance of the brick |

| Kyanite, sillimanite, etc. | As a raw material with heating expansion, it can expand in volume at high temperatures when added to the ingredients, compensating for the shrinkage of the product and ensuring its size and performance stability under high temperature environments |

| Fused corundum, mullite, etc. | Some phosphate bricks will add a small amount of this substance to strengthen the matrix and improve the performance of the brick |

Send inquiry

Please Leave your message you want to know! We will respond to your inquiry within 24 hours!