Product detail

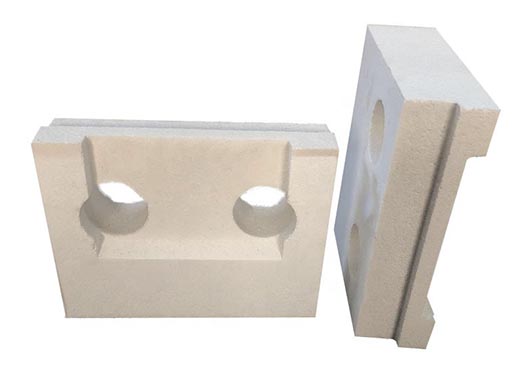

Mullite bricks for hot blast furnace

Mullite brick is a kind of refractory material. It is mainly composed of mullite (3Al₂O₃·2SiO₂). The production process usually involves high – temperature sintering to ensure its excellent performance.

Advantages

High – temperature resistance: Mullite brick can withstand relatively high temperatures. It has good stability at high temperatures and can maintain its structural integrity, generally able to bear temperatures up to about 1800°C.

Good thermal shock resistance: It can endure rapid temperature changes without cracking easily. This property is crucial for applications where the temperature fluctuates frequently.

Chemical stability: It shows excellent resistance to chemical corrosion. It is less affected by acidic and alkaline substances, making it suitable for environments with various chemical substances.

Applications

Ceramic kiln: It is widely used in the lining of ceramic kilns. The high – temperature resistance and chemical stability can ensure the quality of ceramic products during the firing process.

Glass furnace: In glass – making furnaces, mullite brick can be used as the refractory material for the furnace walls and bottom. It can withstand the high – temperature environment of glass melting and help to maintain the stable operation of the furnace.

Metallurgical industry: In some metallurgical furnaces, such as those used for non – ferrous metal smelting, mullite brick is used to line the furnace to resist the high – temperature and corrosive effects of molten metals and slag.

Product Parameters

| Component | Content |

| Mullite (3Al₂O₃·2SiO₂) | Main component, usually above 70% |

| Alumina (Al₂O₃) | Variable content, depending on the grade, about 20 – 30% |

| Silica (SiO₂) | Variable content, about 10 – 20% |

| Trace elements (such as Fe₂O₃, TiO₂, etc.) | Small amounts, usually less than 5% in total |

Send inquiry

Please Leave your message you want to know! We will respond to your inquiry within 24 hours!