Product detail

Mullite bricks for cement kiln

Product Introduction

Raw materials and process: Usually, high-alumina bauxite clinker is used as the main raw material, combined with a small amount of clay or raw bauxite, and fired at high temperature to form sintered mullite bricks; fused mullite bricks are made by melting raw materials such as high-alumina bauxite, industrial alumina and refractory clay by electric melting, and then adding reducing agents to form.

Performance characteristics: high refractoriness, generally above 1790℃; load softening start temperature 1600-1700℃; room temperature compressive strength 70-260MPa; good thermal shock resistance; low thermal conductivity, with good thermal insulation performance.

Application areas

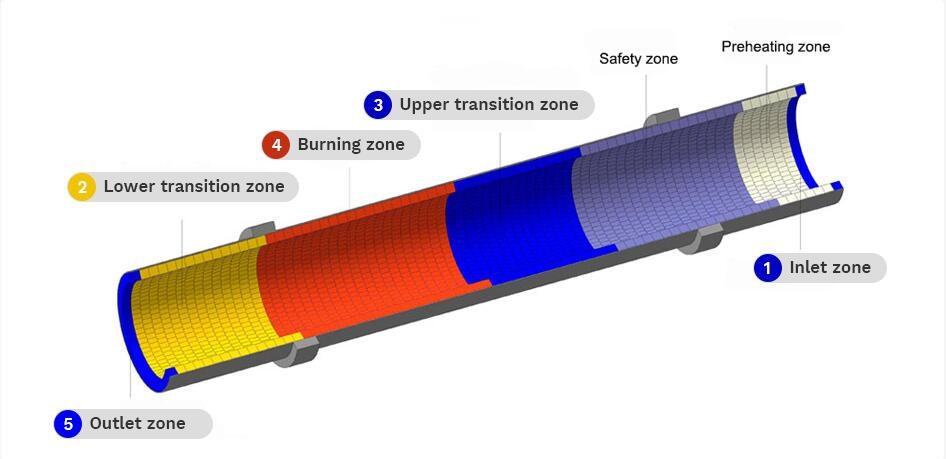

Cement kiln preheating decomposition zone: low-alumina mullite bricks can replace ordinary silica-mullite bricks for cement rotary kiln preheating decomposition zone due to their low thermal conductivity and alkali resistance.

Transition zone and cooling zone of cement rotary kiln: mullite bricks can be used as lining bricks.

Product Parameters

| Composition | Content range |

| Alumina | 65%-75% |

| Silicon dioxide | The remainder, formed with alumina, mainly forms mullite phase (3Al₂O₃・2SiO₂) |

| Other mineral phases | Those with lower alumina content also contain a small amount of glass phase and quartz; those with higher alumina content also contain a small amount of corundum |

Send inquiry

Please Leave your message you want to know! We will respond to your inquiry within 24 hours!