Product detail

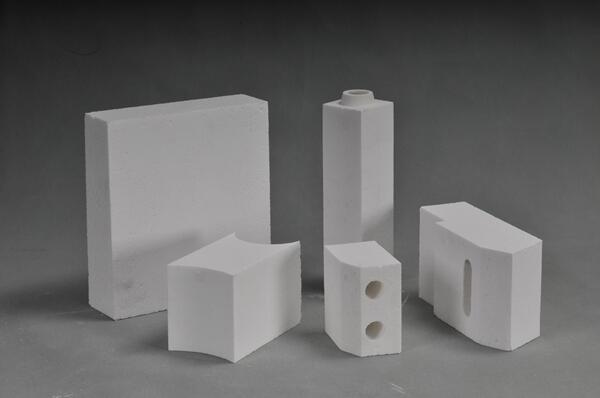

Mullite Brick

Al2o3: ≥72%

Fe2o3: ≤0.8%

Bulk density : ≥2.55g/cm3

Apparent porosity : ≤17%

Cold crushing strength: ≥80Mpa

Thermal shock resistance: Excellent

Mullite bricks are high-alumina refractories with mullite (3Al2O3·2SiO2) as the main crystal phase. Generally, the alumina content is between 70% and 80%. Mullite Refractory bricks have high refractoriness, which can reach above 1790℃. The starting temperature of load softening is 1600~1700℃. It has the good thermal shock resistance with cold crushing strength of 70~260MPa. There are two types of mullite refractories: sintered mullite bricks and fused mullite bricks. If the Al2O3 content in refractory brick is more than 80%, we call it as corundum mullite brick. If there is ZrO2 in the brick, we call it as Zircon Mullite Brick.

As a professional mullite bricks manufacturer, we have exported different mullite refractory bricks to more than 30 countries. Please kindly read the following more information and make Inquiry.

Scope of application

• Mullite bricks are widely used in glass furnaces,hot blast stove and etc

Advantage

• Low thermal expansion rate

• Strong resistance to corrosion by metallurgical slag and various glass liquids

• High temperature wear resistance

• High temperature thermal stability, anti-corrosion of glass liquid

• Long service lifetime

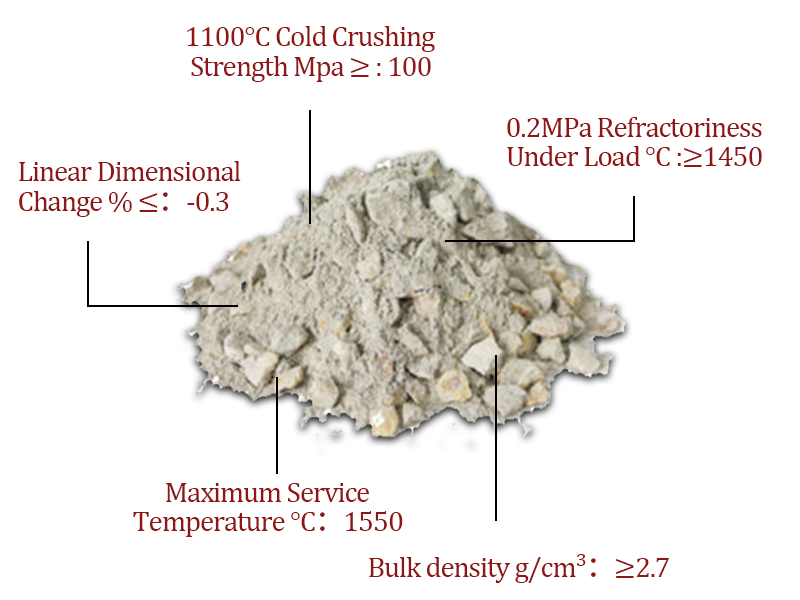

Product Parameters

| Items | Mullite brick M72 | Mullite brick M78 | Mullite brick M80 |

| Al2o3 % | ≥72 | ≥78 | ≥80 |

| Fe2o3 % | ≤0.8 | ≤1.0 | ≤0.5 |

| Bulk density g/cm3 | ≥2.55 | ≥2.65 | ≥2.9 |

| Apparent porosity % | ≤17 | ≤18 | ≤19 |

| Cold crushing strength mpa | ≥80 | ≥80 | 5 |

| Thermal shock resistance | Excellent | Excellent | Very good |

| Softening under load | — | ≤1700 | 1700 |

| Thermal expansion % | — | 0.6 | 0.6 |

Send inquiry

Please Leave your message you want to know! We will respond to your inquiry within 24 hours!