News detail

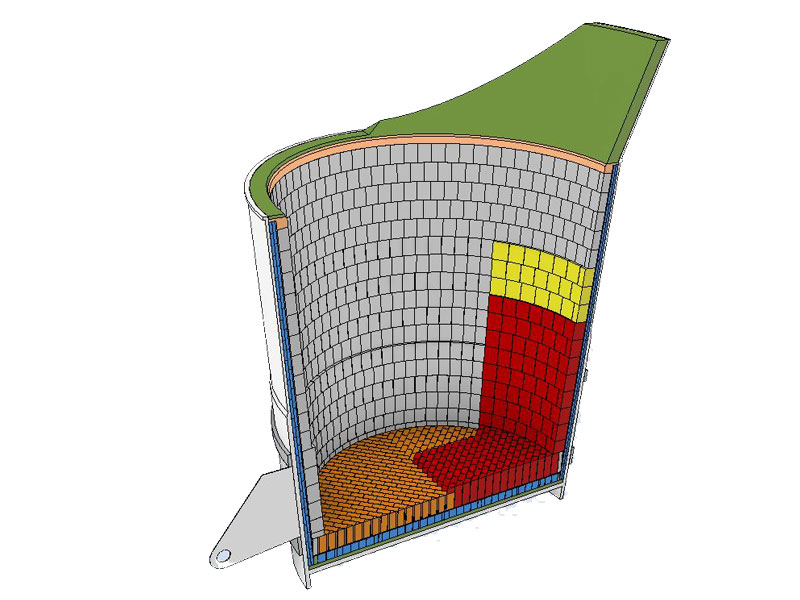

Micro-nano insulation material used in ladle – nano aerogel

Advantages of nano aerogel in ladle application

Nano aerogel is a high-tech nano material with a unique three-dimensional nano porous structure. It has many excellent characteristics such as high porosity, light weight, extremely low density, and high thermal insulation. Its room temperature thermal conductivity is lower than 0.018W/(M・K), and it has excellent high-temperature insulation performance. It can be used in a wide range of temperatures, from -200℃ to 1300℃.

Nano aerogel has shown significant advantages in the application of ladle. Under the condition of the same thickness of thermal insulation material, the outer wall temperature of the ladle using nano aerogel can be reduced by 100-130℃ compared with the outer wall temperature of the ladle using traditional insulation board, which greatly reduces the thermal deformation of the ladle shell and prolongs the service life of the ladle. When the temperature of the outer wall of the ladle is kept the same, the thinner nano aerogel felt can replace the thicker traditional insulation board. For example, the 20mm thick nano aerogel felt can replace the 30mm thick traditional insulation board, so as to achieve the expansion of the ladle, increase the loading capacity of molten steel, and thus improve production efficiency. Moreover, after the use of nano aerogel, the cooling of the molten steel in the ladle is significantly slowed down, which is conducive to stabilizing the temperature of the molten steel, providing more stable temperature conditions for subsequent steel production processes, ensuring the quality of the molten steel, and reducing product quality problems caused by temperature fluctuations.

In addition, nano aerogel also has good chemical stability. It does not decompose, deteriorate, or pulverize during repeated use, and can play a long-term and stable role in heat insulation. At the same time, the materials used to produce nano aerogels do not contain harmful substances and are green and environmentally friendly materials, which meet the requirements of modern industry for environmental protection.

With its excellent performance, nano aerogels show unparalleled advantages over traditional materials in ladle applications, providing strong support for efficient and stable production in the metallurgical industry. With the continuous development of technology and the further reduction of costs, nano aerogel is expected to be more widely used in ladles and more metallurgical equipment, promoting the technological progress of the entire industry.

Cost analysis of nano aerogel in ladle applications

Initial purchase cost: Due to its complex preparation process and high raw material cost, the initial purchase price of nano aerogel is usually higher than that of traditional ladle insulation materials, such as ceramic fiber, rock wool, etc. Calculated by the same volume or area, the purchase cost of nano aerogel may be several times that of traditional insulation materials, which makes many companies have concerns when initially considering material replacement.

Long-term use cost: From the perspective of long-term use, nano aerogel shows cost advantages. On the one hand, its excellent thermal insulation performance can greatly reduce the energy loss caused by heat dissipation of the ladle. In the process of molten steel smelting and transportation, the use of nano aerogel can reduce the cooling range of molten steel and reduce the energy cost consumed due to insufficient temperature. The energy cost saved in the long term is considerable. On the other hand, nano aerogel can effectively extend the service life of the ladle. Due to its good thermal insulation effect, the temperature of the outer wall of the ladle is reduced, the thermal deformation and damage of the ladle shell are reduced, the maintenance and replacement frequency of the ladle is reduced, and the equipment maintenance and replacement costs are saved.

Maintenance cost: Nano aerogel has good chemical stability, does not decompose, deteriorate, or pulverize during repeated use, and does not require frequent replacement or maintenance. Compared with some traditional thermal insulation materials that require regular maintenance and replacement, it requires less manpower and material investment in maintenance, which further reduces the cost of use.

Although the initial purchase cost of nano aerogel is high, it has significant cost-effectiveness in ladle applications based on the long-term use cost and maintenance cost. With the continuous advancement of technology and the expansion of production scale, the cost of nano aerogel is expected to be further reduced, and its application prospects in the ladle and metallurgical fields will be broader. Nano aerogel shows unparalleled advantages over traditional materials in ladle applications, providing strong support for efficient and stable production in the metallurgical industry.

Send inquiry

Please Leave your message you want to know! We will respond to your inquiry within 24 hours!