Product detail

Magnesium Brick for Cement Kiln

Product Overview

Magnesium brick for cement kiln is a high-performance refractory material made of high-quality magnesia sand as the main raw material, which is formed and fired at high temperature. Due to the high content of magnesium oxide (MgO), its main component, it has a series of characteristics that adapt to the harsh working conditions of cement kilns and plays a key role in the cement production process.

Product Performance

High refractoriness: Magnesium bricks have extremely high refractoriness, generally reaching more than 1800℃, and can withstand the extremely high temperature environment in cement kilns. Under long-term high temperature, they can still maintain good physical form and structural stability, and are not prone to softening, melting and other problems.

Excellent alkali resistance: There are a large number of alkaline substances in cement kilns, such as calcium oxide (CaO), potassium oxide (K₂O), etc. These alkaline substances will corrode refractory materials. Magnesium oxide in magnesium bricks has good chemical compatibility with alkaline substances, can effectively resist alkaline erosion, and ensure the stable use of bricks in the alkaline environment of cement kilns.

Good high temperature strength: Under high temperature conditions, magnesium bricks can still maintain high strength, and the strength will not drop significantly due to temperature increases. This enables it to maintain the integrity of its structure and reduce damage caused by external forces when it is subjected to the extrusion, scouring and mechanical vibration of materials in the kiln.

Application scenarios

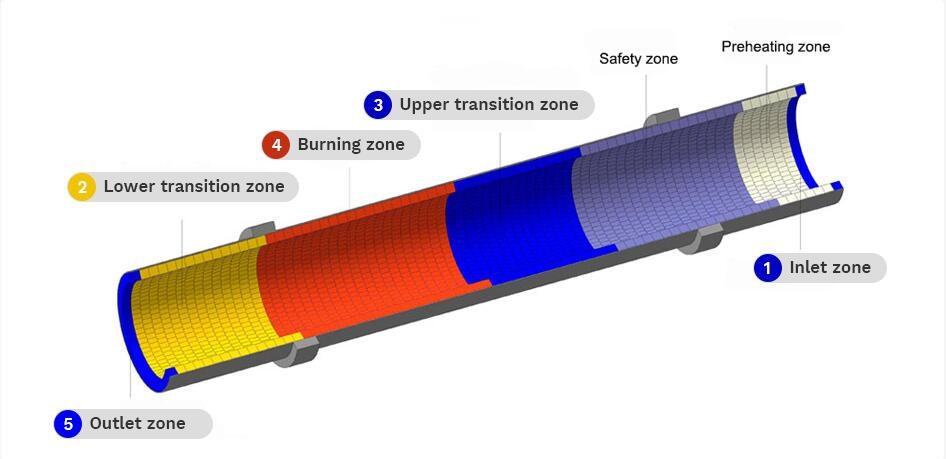

Cement kiln burning zone: This area is the key part of cement clinker formation, with a temperature of up to 1450℃ – 1600℃ and accompanied by a large amount of erosion by alkaline materials. With its high refractoriness and excellent alkali resistance, magnesia bricks have become one of the preferred refractory materials for the burning zone. It can effectively resist the erosion of high-temperature flames and alkaline clinker and extend the service life of the kiln lining.

Cement kiln transition zone: The temperature in the transition zone changes frequently and there is a certain amount of alkaline erosion. The good thermal shock resistance and alkali resistance of magnesia bricks enable it to adapt to the complex working conditions in this area, reduce the risk of damage caused by temperature fluctuations and erosion, and ensure the stable operation of the cement kiln.

Product Parameters

| Ingredients | Content (%) | Function |

| MgO | 85 – 95 | It is the main component of magnesia bricks, which gives magnesia bricks high refractoriness, excellent alkali resistance and good high temperature performance. Its content directly affects the quality and performance of magnesia bricks. |

| CaO | 1-3 | An appropriate amount of calcium oxide can adjust the sintering performance and mineral composition of magnesia bricks to a certain extent, optimize the microstructure of the brick body, and improve its high temperature strength and corrosion resistance. However, too high a content may cause the volume stability of the brick body to deteriorate. |

| SiO₂ | 1-3 | At high temperatures, silica will react with components such as magnesium oxide to form some low melting point mineral phases, which will affect the high temperature performance of magnesia bricks. Therefore, its content needs to be strictly controlled to ensure the quality of magnesia bricks. |

| Fe₂O₃ | 0.5 – 2 | The content of iron oxide in magnesia bricks is low, and it will participate in some high temperature reactions, which will have a certain impact on the mineral composition and performance of magnesia bricks. Reasonable control of iron oxide content helps to improve the comprehensive performance of magnesia bricks. |

| Other additives (such as mineralizers, etc.) | Appropriate amount | These additives can promote the sintering process of magnesia bricks, improve the microstructure of bricks, increase their density and strength, and further enhance the performance of magnesia bricks. |

Send inquiry

Please Leave your message you want to know! We will respond to your inquiry within 24 hours!