Product detail

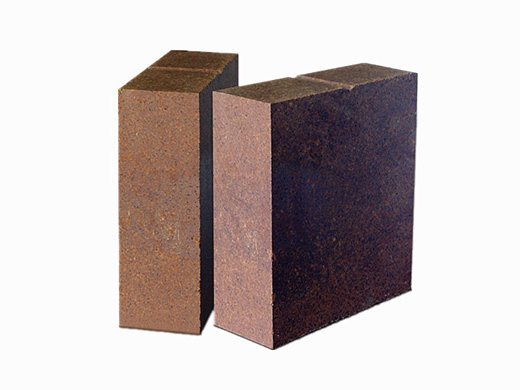

Magnesite-chrome bricks

Product Introduction

Magnesite-chrome bricks are refractory materials renowned for their excellent high-temperature resistance and good resistance to chemical corrosion. They are typically manufactured by mixing magnesia (MgO) and chromite (Cr₂O₃) raw materials, followed by high-temperature firing processes. These bricks possess a dense structure and relatively high mechanical strength, enabling them to endure harsh operating conditions in industrial furnaces.

Applications

Steelmaking Industry: Widely used in basic oxygen furnaces (BOF) and electric arc furnaces (EAF). In BOFs, they can withstand the severe thermal shock and chemical erosion caused by the reaction between molten steel and slag. In EAFs, they help maintain the integrity of the furnace lining during the melting and refining of scrap steel.

Cement Kilns: Applied in the high-temperature zones of cement rotary kilns. They resist the alkaline substances and high temperatures present during the cement clinker production process, prolonging the service life of the kiln lining and ensuring the stable operation of cement production.

Non-ferrous Metal Smelting: Utilized in furnaces for smelting non-ferrous metals such as copper and nickel. They can tolerate the corrosive environment and high temperatures associated with the smelting of these metals.

Product Parameters

| Chemical Component | Content Range |

| Magnesia (MgO) | 40% – 60% |

| Chromite (Cr₂O₃) | 8% – 20% |

| Alumina (Al₂O₃) | 5% – 15% |

| Iron Oxide (Fe₂O₃) | 8% – 15% |

| Other Minor Components | Small amounts |

Send inquiry

Please Leave your message you want to know! We will respond to your inquiry within 24 hours!