Product detail

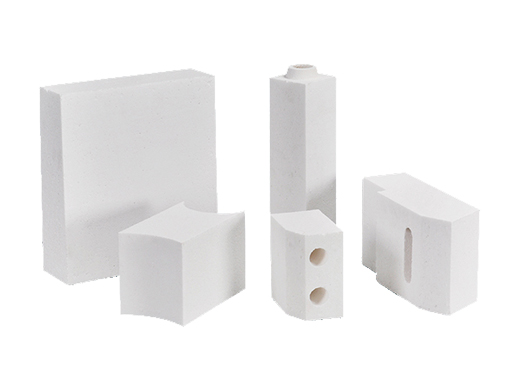

Magnesia Chrome Brick

Composition:MgO + Cr2O3

Application:Open hearth, electric furnace, refining furnace, etc

Cr2O3:8-20%

Refractoriness Under Load:≥1550℃

Size:As your requirements

Main Raw Material:DBM & Chrome Ore

Refractoriness:1790℃

Capacity: 500 tons per Month

Product Introduction

Magnesia chrome brick is adopts dead burnt magnesite and chrome ore as raw material, by adding micro powder and other additives, after mixing, shaping, drying, sintering at high temperature in tunnel kiln.

Features

1.Good abrasion resistance.

2.Good thermal shock resistance.

3.Good acid and alkali resistance.

Application

Magnesia Chrome bricks are mainly used for the metallurgical industry, burning zone of rotary kiln, regenerator of glass kiln, etc.

Product Parameters

| Item | Magnesia Chrome Brick | |||

| MC-20 | MC-18 | MC-12 | MC-8 | |

| Cr2O3 (%) | >=20 | >=18 | >=12 | >=8 |

| MgO(%) | >=40 | >=45 | >=55 | >=60 |

| Apparent Porosity(%) | <=23 | <=23 | <=23 | <=23 |

| Cold Crushing Strength (Mpa) | >=24.5 | >=24.5 | >=24.5 | >=24.5 |

| Refractoriness Under Load (0.2MPa,0.6%)(℃) | >=1550 | >=1550 | >=1550 | >=1550 |

Send inquiry

Please Leave your message you want to know! We will respond to your inquiry within 24 hours!