Product detail

Magnesia Carbon Brick

Magnesia carbon brick is a refractory material made of high-melting-point alkaline magnesium oxide (melting point 2800 ° C) and high melting point carbon material which is difficult to be infiltrated by slag, adding various non-oxide additives and combining carbonaceous binder. Magnesia carbon bricks are mainly used in converters, AC arc furnaces, linings of DC arc furnaces, slag lines of ladle, and the like.

Usually, the melting loss of magnesia carbon brick is carried out by reacting magnesia with slag on the working surface. The melting loss rate depends on the nature of the magnesia itself and on the size of the magnesia particles. Larger particles have higher corrosion resistance, but they are more likely to escape from the working face of the magnesia carbon brick to the slag. Once this happens, the rate of damage of the magnesia carbon brick will be accelerated.

The absolute expansion of large particles of magnesia is larger than that of small particles. In addition, the expansion coefficient of magnesia is much larger than that of graphite. Therefore, in the MgO-C brick, the large particle/graphite interface of magnesia is produced at the interface of small particles/graphite of magnesia. The stress is large, and the crack generated is also large, which indicates that the critical grain size of the magnesia in the MgO-C brick is small, which has the effect of relieving thermal stress.

From the aspect of product performance, the critical particle size becomes smaller, the open pores of the product decrease, and the pore diameter becomes smaller, which is beneficial to the improvement of the oxidation resistance of the product; at the same time, the internal friction between the materials is increased, the molding is difficult, and the density is lowered. Therefore, in the production of MgO-C bricks, it is very difficult to generalize the critical particle size of magnesia-silica. It is often necessary to determine the critical particle size of the magnesia based on the specific conditions of use of the MgO-C brick. In general, MgO-C bricks used in places with large temperature gradients and intense thermal shocks need to choose a smaller critical particle size; while those requiring high corrosion resistance, the critical grain size required is required.

1. Magnesia fine powder

In order to maintain the overall uniformity of the thermal expansion of the particles and the matrix portion of the MgO-C brick, the matrix portion needs to be mixed with a certain amount of fine powder of magnesia, and also the structure maintains a certain integrity after partial oxidation of the matrix.

However, if the fine powder of magnesia is too fine, the reduction rate of MgO will be accelerated, thereby accelerating the damage of the MgO-C brick. Magnesia sand less than 0.01mm is easy to react with graphite, so it is best not to mix such too fine magnesia when producing MgO-C bricks. In order to obtain MgO-C bricks with excellent performance, the ratio of magnesia to graphite of less than 0.074 mm in MgO-C bricks should be less than 0.5, and if it exceeds 1, the porosity of the matrix portion is sharply increased.

2. The amount of graphite added

The amount of graphite added should be considered in combination with different bricks and different parts of the brick. In general, if the amount of graphite added is less than 10%, it is difficult to form a continuous carbon network in the product, and the carbon may not be effectively exhibited; the amount of graphite added is more than 20%, the molding is difficult during production, cracks are easily generated, and the product is easily oxidized. Therefore, the amount of graphite added is generally between 10% and 20%. According to different parts, different amounts of graphite are selected. The melting loss of MgO-C bricks is governed by the oxidation of graphite ink and the dissolution of MgO into the slag. Increasing the graphite can reduce the erosion rate of slag, but it increases the oxidation of gas phase and liquid phase. Damaged.

3. Mixing

The graphite is light in density and tends to float on top of the mix during mixing, making it incompletely in contact with other components in the furnish. High speed mixers or planetary mixers are generally used. When producing MgO-C bricks, if the feeding order is not paid attention to during the mixing, the plasticity and formability of the slurry will be affected, thereby affecting the yield and performance of the product.

The correct order of addition is: magnesia (coarse, medium) → binder → graphite → magnesia powder and additives mixed powder. The mixing time varies slightly depending on the mixing equipment. If the mixing time is too long, the graphite and the fine powder around the magnesia are easily peeled off, and the mud is dried due to the large amount of solvent in the binder; if it is too short, the mixture is uneven and the plasticity is poor, which is not favorable for molding. .

4. Molding

Molding is an important way to increase the packing density and densify the structure of the product. Therefore, high-pressure molding is required, and the pressing is strictly carried out according to the operating procedure of light weight, heavy weight and multiple pressurization. When producing MgO-C bricks, the density of bricks is commonly used. Controlling the forming process, the higher the tonnage of the general press, the higher the density of the brick, and the less binder required for the mixture (otherwise, due to the shortening of the distance between the particles and the thinning of the liquid film, the bonding agent is partially localized, resulting in several The structure of the product is not uniform, which affects the performance of the product and also causes the elastic aftereffect to cause the brick to crack.

5. Hardening treatment

The phenolic resin-bonded MgO-C brick can be heat treated at a temperature of 200 to 250 ° C. The resin can be directly (thermosetting resin) or indirectly (thermoplastic resin) hardened to give the product a high strength, and the general processing time is 24 ~32h, of which 50~60°C needs to be kept warm due to resin softening; 100~110°C needs to be kept warm due to large amount of solvent evaporation; 200~250°C needs heat preservation due to condensation hardening of the bonding agent.

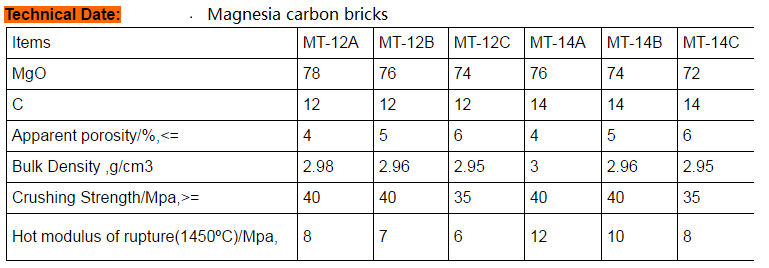

Product Parameters

Send inquiry

Please Leave your message you want to know! We will respond to your inquiry within 24 hours!