Product detail

Magnesia Brick

Apparent Porosity :≤18%

Cold Crushing Strength: ≥55Mpa

0.2Mpa Refractoriness Under Load T0.6: ≥1650

Bulk Density :≥2.95g/cm3

Thermal Stability 950°C Wind cycles:≥15

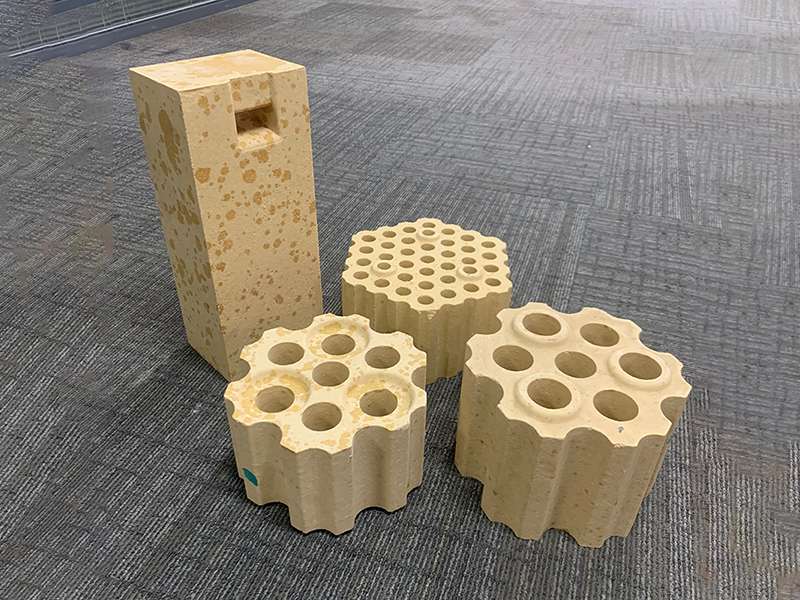

Magnesia Brick Brief Description

Magnesia bricks are basic refractory bricks. Its magnesia content is from 92% to 97.7%, and cristobalite is as the main crystal phase.Magnesite bricks are generally divided into bonded magnesia refractory bricks and chemical combination magnesia bricks.Magnesia bricks have excellent performance of resistance to alkaline slag,so this kind firebricks are widely used in glass industry, cement industry,steel and iron industry,etc.

Magnesia Brick Catogeries

Magnesite bricks are generally divided into two types:

A) Sintered magnesite bricks

This kind of magnesia refractory bricks include direct combined magnesia bricks and recombined magnesia bricks, and fused magnesia bricks, which are made of natural magnesia sand and fired at the high temperature of 1650 to 1750 ℃, which will be used in high temperature requirement working environment,like the regenerator part of glass furnace. Fused magnesia bricks are taken fused magnesia sand as raw material and fired in the high tempreture tunnel klin. Some people have an incorrect idea the fused magensia bricks are made by casting method.

B) Unburned magnesite bricks

This kind of magnesia bricks include chemical bonded magnesia brick and asphalt bonded magnesite brick, which will be used in low temperature requirement working environment.Chemical bonded magnesia bricks are made with some chemical binders through being shaped and dried.

As a professional magnesia bricks manufacturer, Zhengzhou Shennan Refractroy Co.,ltd can produce different high-quality bonded magnesia refractory bricks according to the customers requirements.

Magnesia Bricks Applications

a) In the glass furnace:

grids and heat exchangers of regenerators in the glass furnace, like magnesia checker bricks

b) In the iron and steel industry: steelmaking furnace linings, ferroalloy kilns, and iron mixing furnaces

c) In non-ferrous metallurgical industry furnaces, such as copper, lead, zinc, and side furnace linings;

d) In the building materials industry, such as magnesia bricks in lime kiln, magnesia spinel bricks in the cement rotary kiln.

e) In high-temperature calcining kilns, shaft kilns and tunnel kilns in the refractory manufacturing industry.

Magnesia Bricks Advantages

• High refractoriness

• Good alkali corrosion resistance and slag resistance

• High load softening starting temperature

• High purity Less pollution to glass liquid

• Long service life and high tempreture resistance

Magnesia Brick Manufacturing Process

The main raw material of magnesia brick is magnesia sand. Sintered magnesia bricks are made of magnesia clinker. After being crushed, batched, kneaded, and shaped, they are fired at a high temperature of 1550 to 1650°C. The firing temperature of high-purity products is above 1750°C. Fused magnesia bricks also belongs to sintered magenesia refractory bricks.Non-burn magnesia bricks are made by adding appropriate chemical binders to magnesia, mixing, molding, and drying.

Magnesia Brick Usage Notes

Magnesia brick has strong resistance to alkaline slag, but it cannot resist the erosion of acid slag. At a high temperature of 1600℃, it can react with silica bricks, clay bricks and even high alumina bricks. Generally, neutral bricks are used to separate with those bricks. The refractoriness of magnesia brick is above 2000℃, but its softening point under load is only 1500~1550℃. Moreover, the temperature interval from softening to 40% deformation is very small, only 30~50℃ difference, and the thermal stability of magnesia bricks is also poor, which is an important reason for the damage of magnesia bricks. The conductivity of magnesia brick at room temperature is very low, but it cannot be ignored at high temperature (such as 1500℃). If it is used at the bottom of electric furnace, attention should be paid.

Magnesia Brick Manufacturers

There are more than 100 manufactuers of magnesia bricks in China,but the quality is quite different.The buyers should not consider too much on low price to choose the supplier.

Product Parameters

| Item | Index | ||||

| DMZ-95 | DMZ-96 | DMZ-97 | DMZ-98 | ||

| Chemical composition | MgO % | ≥95 | ≥96 | ≥97 | ≥97.5 |

| SiO2 % | ≤1.5 | ≤1.2 | ≤1.0 | ≤0.5 | |

| CaO % | ≤1.5 | ≤1.2 | ≤1.2 | ≤0.6 | |

| Apparent Porosity % | ≤18 | ≤18 | ≤17 | ≤15 | |

| Cold Crushing Strength Mpa | ≥55 | ≥60 | ≥60 | ≥60 | |

| 0.2Mpa Refractoriness Under Load T0.6 | ≥1650 | ≥1680 | ≥1700 | ≥1700 | |

| Bulk Density g/cm3 | ≥2.95 | ≥3.0 | ≥3.05 | ≥3.05 | |

| Thermal Stability 950°C Wind cycles | ≥15 | ≥20 | ≥20 | ≥20 | |

Send inquiry

Please Leave your message you want to know! We will respond to your inquiry within 24 hours!