Product detail

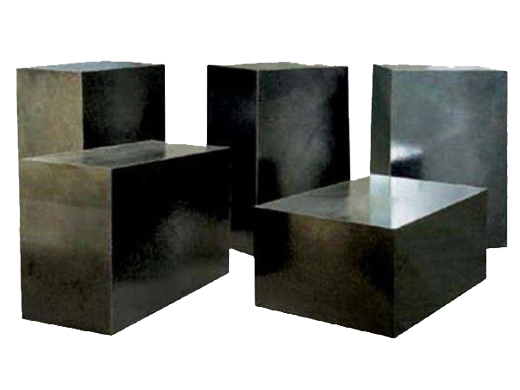

Magnesia Alumina Spinel Brick

Composition:MgO + Al2O3/Fe2O3/ZrO2

Application:Cement and lime Kiln, or other industrial kilns.

Color:Brown

Raw Material:DBM & Spinel

Refractoriness:≥1790℃

Capacity:500 tons per month

Package:Export wooden pallets

Product Introduction

Magnesia spinel bricks are refractory products made of periclase and magnesia alumina spinel ,which can improve the heat stability of common magnesia brick.

Features

1.Excellent Heat Stability.

2.Better Anti-stripping performance than direct bonded magnesia chrome brick.

3.Abrasion Resistant.

4.High Refractoriness Under Load.

Application

It’s mainly used for burning zone and transition zone of cement kiln, also some other industrial furnaces.

Product Parameters

| Product | Magnesia Alumina Spinel Bricks | Magnesia AluminaSpinel Zirconium Bricks | Magnesia Spinel Bricks | Magnesia Alumina Zirconium Bricks | |||||||||

| Model | MLJ-85A | MLJ-93A | MLJ-95A | MLJ-85B | MLJ-93B | MLJ-95B | MLJZ-93A | MLJZ-93B | MLJZ-R63A | MLJZ-R63B | MZ-96A | MZ-94B | |

| MgO% >= | 85 | 88 | 93 | 82 | 85 | 90 | 92 | 88 | 85 | 80 | 92 | 88 | |

| Al2O3 >= | 9 | 5 | 3 | 9 | 5 | 3 | 5 | 5 | 3 | 3 | 5 | 5 | |

| Fe2O3<= | 0.7 | 0.7 | 0.7 | 0.8 | 0.8 | 0.8 | 0.7 | 0.8 | 7.5 | 7.5 | 0.8 | 0.9 | |

| SiO2 <= | 0.6 | 0.8 | 0.7 | 2.5 | 2 | 2.5 | 1 | 2.5 | 0.9 | 2.0 | 1 | 2.5 | |

| ZiO2>= | 1-3 | 1-3 | 1-3 | 1-3 | |||||||||

| Apparent Porosity<= | 16-18 | 16-18 | 16-18 | 17-18 | 17-18 | 17-18 | 17-18 | 17-18 | 16-17 | 16-17 | 17-19 | 17-19 | |

| Bulk Density>= | 2.85 | 2.85-3.0 | 2.85 | 2.8 | 2.85 | 2.82 | 2.85 | 2.8 | 30. | 2.9 | 2.9 | 2.8 | |

| Cold Crushing Strength>= | 45 | 45 | 45 | 40 | 40 | 40 | 50 | 50 | 50 | 45 | 50 | 45 | |

| 0.2.Mpa Refractoriness Under Load(℃)>= | 1700 | 1700 | 1700 | 1700 | 1700 | 1700 | 1700 | 1660 | 1660 | 1630 | 1700 | 1650 | |

| Thermal Expansion1400℃ | 1.6 | 1.6 | |||||||||||

| Thermal Shock Resistance | 1100℃ water cooling, times | 12 | 12 | 12 | 10 | 10 | 10 | 12 | 10 | 10 | 8 | 8 | 6 |

| 950℃water cooling, times | 100 | 100 | 100 | 80 | 80 | 80 | 100 | 80 | 100 | 80 | 30 | 25 | |

| Heat Conductivity | 2.8 | 2.9 | 3.0 | 2.8 | 2.9 | 3.0 | 3.0 | 2.9 | 2.5 | 2.5 | 4.5 | 4.4 | |

Send inquiry

Please Leave your message you want to know! We will respond to your inquiry within 24 hours!