Product detail

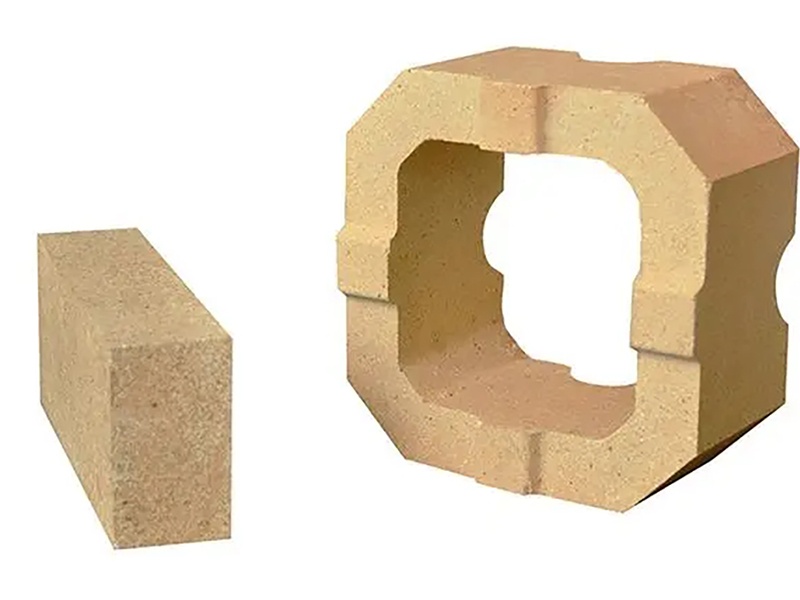

Low Porosity Brick

Low Porosity Brick are made of low-alumina mullite as the main raw material, through high-pressure molding and high-temperature sintering. The main mineral composition is mullite phase, and the product has excellent high-temperature physical properties and chemical erosion resistance. High Duty Firebricks have good stability, the degree of erosion does not change suddenly, the service life is 2 to 3 times longer than that of ordinary clay bricks. The thermal conductivity, specific heat and solubility are 2 times, 10% and 40% higher than ordinary clay bricks respectively, and the heat storage capacity is 50% to 60% higher than ordinary clay bricks, which can improve the thermal efficiency of the kiln.

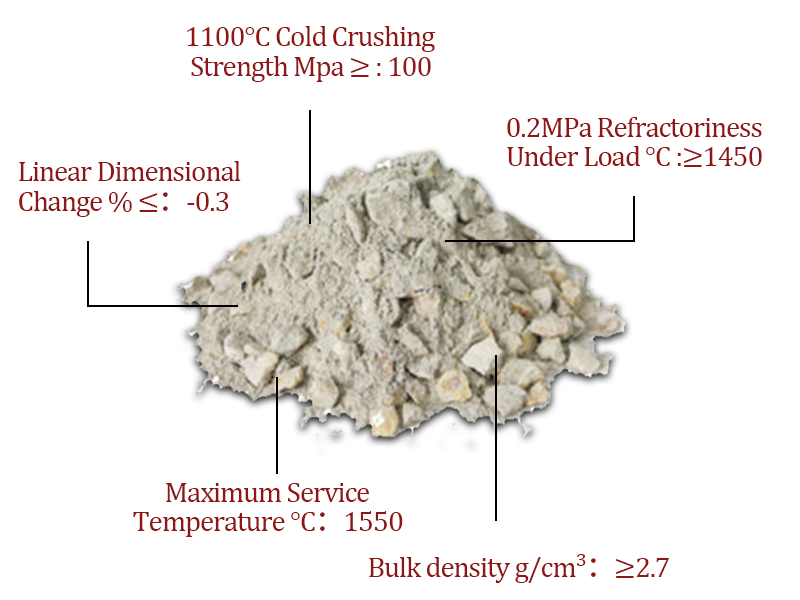

Features of low-porosity clay bricks:

1. Low apparent porosity

2. High refractoriness under load

3. High cold crushing strength

4. Good high-temperature volume stability and good wear resistance;

5. Good anti-penetration and anti-corrosion performance

Therefore, it is often used in environments with chemical erosion and large temperature fluctuations, and is applied to steel, glass, chemical and other industries. The effect is quite obvious when used in the regenerator of the glass kiln and the use of iron ladle.

Product Parameters

| Item | Grade | |||

| DN-12 | DN-15 | DN-17 | ||

| Chemical Composition | Al2O3 (%) | 45 | 45 | 42 |

| Fe2O3 (%) | 1.2 | 1.6 | 2 | |

| CaO+MgO (%) | 0.6 | 0.6 | 0.7 | |

| Na2O+K2O (%) | 0.8 | 0.8 | 0.8 | |

| Physical Properties | Bulk Density (g/cm3) | 2.37 | 2.3 | 2.2 |

| Apparent Porosity (%) | 12 | 15 | 17 | |

| Cold Crushing Strength (Mpa) | 90 | 80 | 60 | |

| 0.2Mpa Refractoriness under Load (℃) | 1500 | 1480 | 1450 | |

| Linear Change on Reheating (1400℃*25h,0.2Mpa)(%) | ±0.1 | ±0.1 | ±0.1 | |

| Thermal Expansion(20-1000℃)(%) | 0.3 | 0.5 | 0.7 | |

Send inquiry

Please Leave your message you want to know! We will respond to your inquiry within 24 hours!