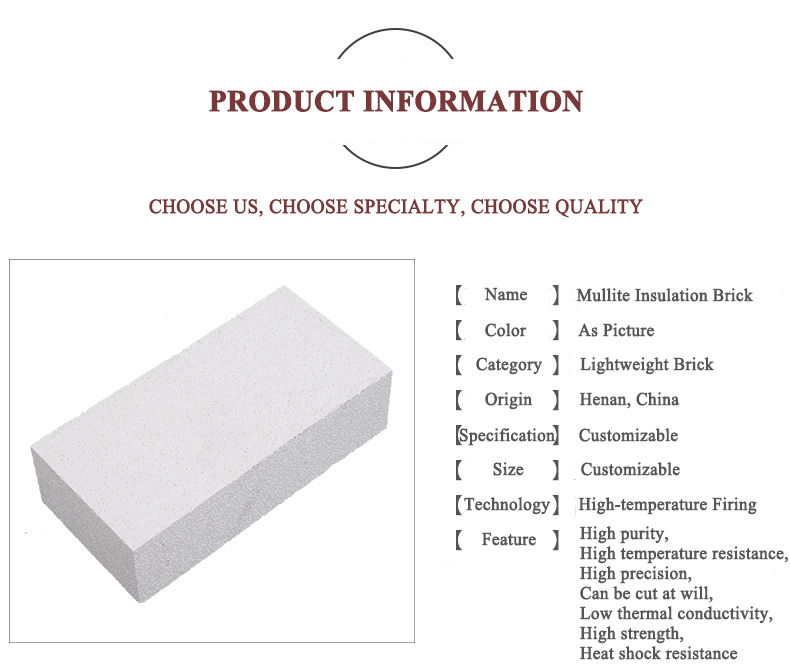

Product detail

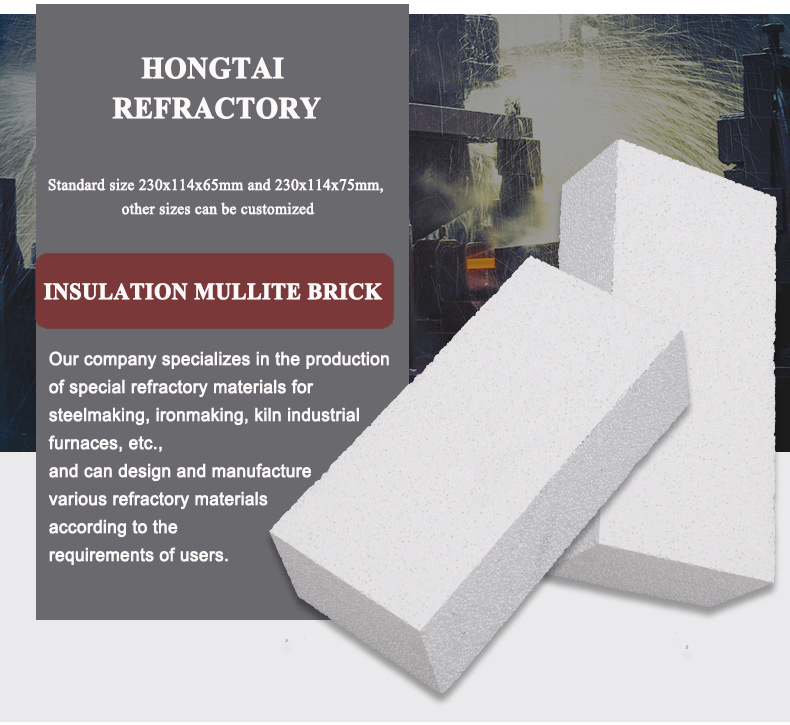

Lightweight Mullite Fire Bricks

Main Composition:Al2O3+SiO2

Application:Insulation layer for various kinds of industrial furnaces

Al2O3:37-77%

Color:White

Standard Size:230*114*65 mm

Raw Material:Mullite

Classification temperature:1260-1730℃

Package:Export wooden pallets and polyboard

Light weight mullite fire brick are made of high-quality and high-purity refractory materials, according to the specific gravity of the product, with organic compound fillers, vacuum extrusion molding, and high-temperature sintering to synthesize lightweight mullite products. With its light weight and excellent thermal insulation performance, light weight mullite fire brick are widely used in the hot surface refractory lining or insulation layer of a variety of thermal equipment, creating conditions for improving the energy efficiency of the equipment.

High alumina refractories with mullite as the main crystal phase generally have an alumina content between 50% and 75%. The refractory temperature of mullite lightweight firebrick can reach above 1790℃. The starting temperature of load softening is 1600-1700℃. Pressure resistance at room temperature is slightly 70-260MPa. Good thermal shock resistance. There are two types of sintered mullite insulating firebricks and fused mullite insulating firebricks.

Sintered mullite insulating firebricks are made of high-alumina bauxite clinker as the main raw material, adding a small amount of clay or raw bauxite as a binder, and forming and firing. Fused mullite insulating firebricks use high alumina bauxite, industrial alumina and refractory clay as raw materials, add charcoal or coke fine particles as reducing agents, and are manufactured by reduction fusion method after molding. The crystalline fused mullite is larger than that of sintered mullite, and its thermal shock resistance is better than that of sintered products. Their high temperature performance mainly depends on the content of alumina and the uniformity of mullite phase and glass distribution.

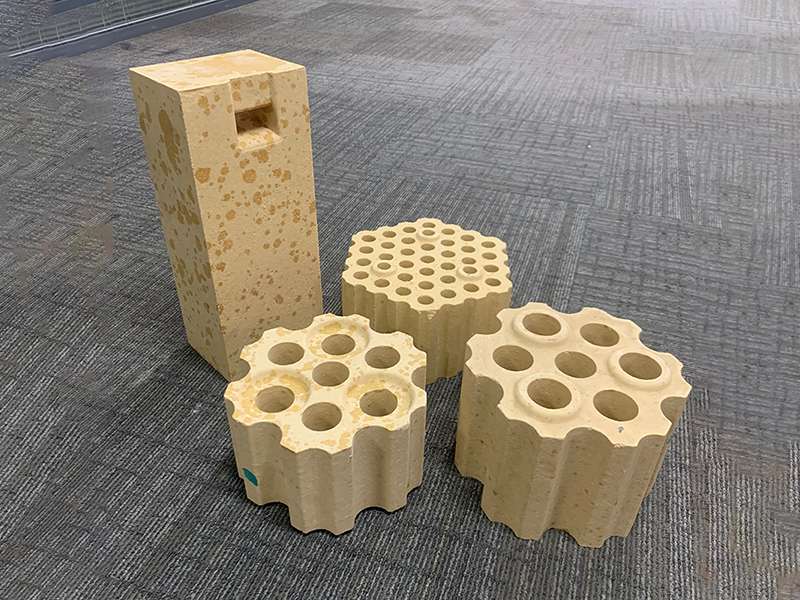

A high-alumina refractory with mullite (3Al2O3·2SiO2) as the main crystal phase. Generally, the alumina content is between 65% and 75%. In addition to mullite, the mineral composition with lower alumina also contains a small amount of glass phase and cristobalite; the higher alumina content also contains a small amount of corundum. light weight mullite fire brick can be directly used for the lining of high-temperature kilns, and have been widely used in shuttle kilns, roller kilns, glass and petrochemical kilns.

Product Parameters

| Item | JM23 | JM 26 | JM28 | JM 30 |

| Chemical Composition (%) | ||||

| Al2O3 | 50 | 60 | 65 | 70 |

| SiO2 | 47 | 37 | 32 | 27 |

| Fe2O3 | <=1 | <=1 | <=1 | <=1 |

| K2O + Na2O | 1.1 | 1.7 | 1.7 | 1.7 |

| Physical Properties | ||||

| Density (g/cm3) | 0.6 | 0.8-1.0 | 0.9-1.1 | 1.0-1.2 |

| Classification Temperature (℃) | 1260 | 1430 | 1540 | 1650 |

| Cold Crushing Strength (MPa) | 1.3 | 3 | 3.5 | 3.5 |

| Modulus of Rupture (MPa) | 1 | 1.7 | 2.3 | 3.1 |

| Permanent Linear Change (%) x 24hrs | <=0.6 | <=0.6 | <=0.8 | <=0.9 |

| Thermal Expansion (%) 1000℃ | 0.5 | 0.52 | 0.52 | 0.53 |

| Thermal Conductivity (W/m.k) | ||||

| 350℃ | 0.18 | 0.25 | 0.33 | 0.38 |

| 400℃ | 0.25 | 0.29 | 0.35 | 0.4 |

| 600℃ | 0.24 | 0.32 | 0.37 | 0.42 |

Send inquiry

Please Leave your message you want to know! We will respond to your inquiry within 24 hours!