Product detail

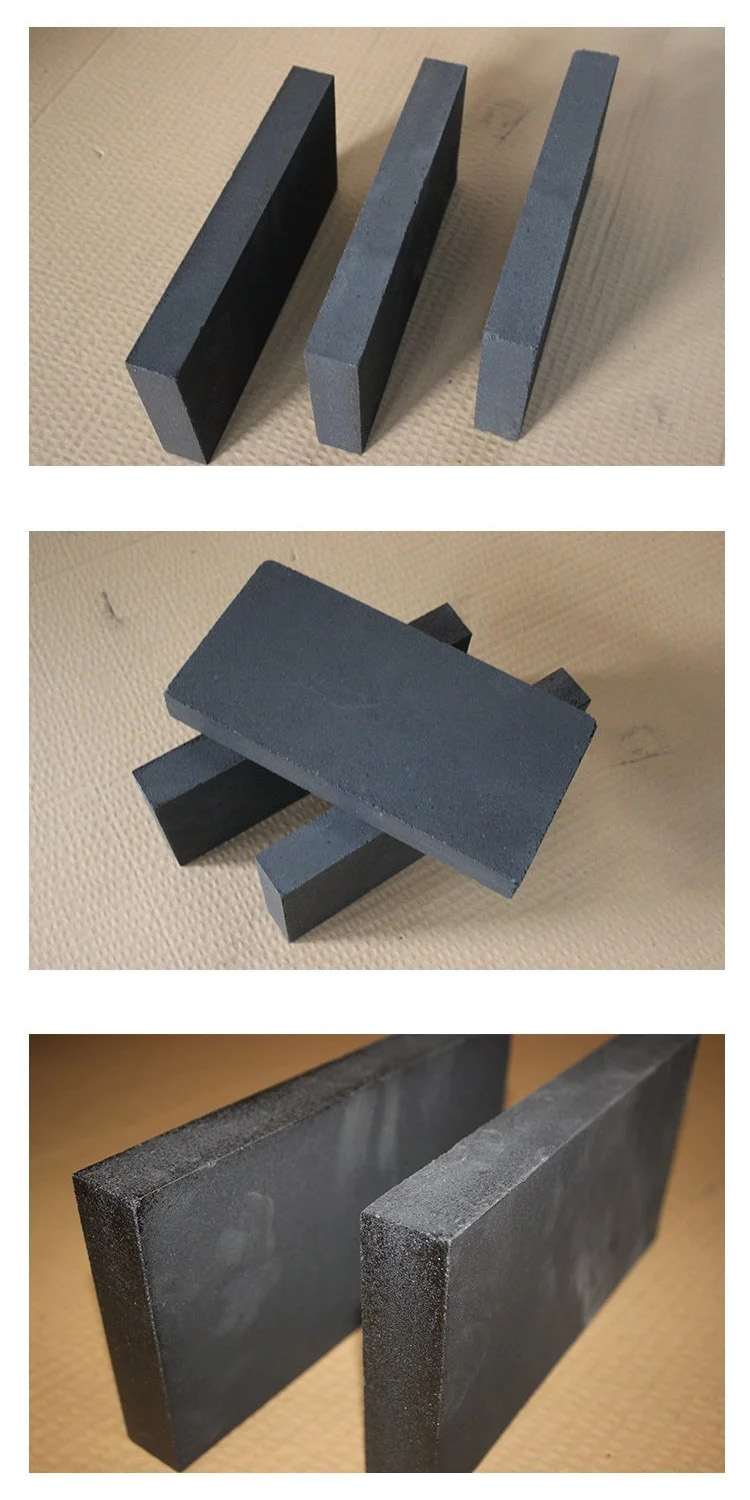

Impregnated Carbon Bricks

Graphite impregnated carbon bricks are high temperature resistant neutral refractory products made of carbonaceous materials as raw materials and adding appropriate amount of binders. Carbon brick raw materials include anthracite, coke and graphite, as well as asphalt, tar and anthracene oil binders. Anthracite has less volatile matter and dense structure. When producing carbon bricks, it is often used as aggregate, metallurgical coke is added, and asphalt is used as a binder. The technical requirements of graphite impregnated carbon bricks are generally carbon content>97%; mechanical strength>25MPA; ash content≤1.5%. The external dimensions are strictly required, and general products must undergo certain mechanical processing.

Application of Impregnated Carbon Bricks

1. Phosphoric acid reaction tank

2. Phosphoric acid washing tower lining

3. Phosphoric acid, hydrochloric acid, and hydrofluoric acid storage tank lining

4. Power plant desulfurization tower and chimney lining

Product Parameters

| Density |

1.65 gms/cc

|

| Porosity |

4 %

|

| Thermal Conductivity |

4 – 6 w/mk

|

| Thickness |

10 To 100 mm

|

| Compressive Strength |

600 kg/cm2

|

| Flexural Strength |

300 kg/cm2

|

| Tensile Strength |

125 kg/cm2

|

| Water Absorption |

2 %

|

| Abradability Index |

140 on Morgan Scale

|

| Carbon Content |

97 – 99 % Min.

|

| Ash Content |

1.5 % Max.

|

| Temperature Resistivity |

Upto 180 Degree C

|

Send inquiry

Please Leave your message you want to know! We will respond to your inquiry within 24 hours!