Product detail

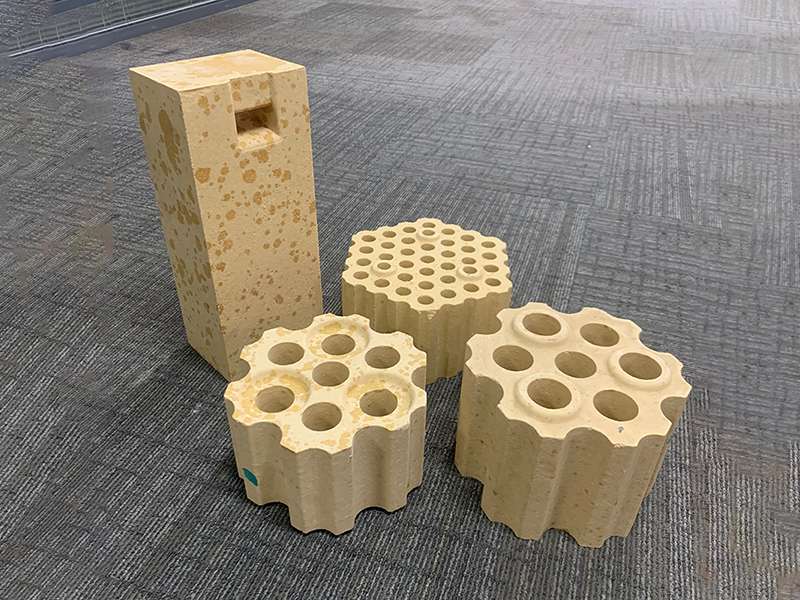

High Quality Silica Brick

High-quality silica bricks are mainly used for the partition walls of carbonization chambers and combustion chambers of coke ovens, regenerators and slag chambers of steel-making open-hearth furnaces, soaking furnaces, refractory materials of glass melting furnaces, and ceramic firing kilns. The roof and other load-bearing parts are also used for the high-temperature load-bearing parts of hot blast stoves and the roof of acid open hearth furnaces.

Product Parameters

| 项目 Item |

优质硅砖 High Quality Silica Brick |

|||

| GB-96A | GB-96B | GB-95A | GB-95B | |

| SiO2 (%) | ≥96 | ≥96 | ≥95 | ≥95 |

| Fe2O3 (%) | ≤0.6 | ≤1.0 | ≤1.2 | ≤1.2 |

| 熔融指数(%) Melt Index |

≤0.5 | ≤0.5 | — | — |

| 显气孔率(%) Apparent Porosity |

≤21 | ≤21 | ≤22 | ≤22 |

| 真密度(g/cm3) True Density |

≤2.34 | ≤2.34 | ≤2.34 | ≤2.34 |

| 常温耐压强度(Mpa) Cold Crushing Strength |

≥40 | ≥40 | ≥30 | ≥30 |

| 荷重软化开始温度(℃) (0.2Mpa) Refractoriness under Load |

≥1680 | ≥1670 | ≥1660 | ≥1650 |

| 残余石英 (%) Residual Quartz |

≤3.0 | ≤3.0 | ≤3.0 | ≤3.0 |

| 重烧线变化率 (%) (1450℃x2h) Reheating Linear Change Rate |

0-0.2 | 0-0.2 | 0-0.2 | 0-0.2 |

| 典型应用 Typical Application |

优质硅砖主要用于炼焦炉的炭化室和燃烧室的隔墙、炼钢平炉的蓄热室和沉渣室、均热炉、玻璃熔窑的耐火材料和陶瓷的烧成窑等窑炉的拱顶和其他承重部位,也用于热风炉的高温承重部位和酸性平炉炉顶。 High-quality silica bricks are mainly used for the partition walls of carbonization chambers and combustion chambers of coke ovens, regenerators and slag chambers of steel-making open-hearth furnaces, soaking furnaces, refractory materials of glass melting furnaces, and ceramic firing kilns. The roof and other load-bearing parts are also used for the high-temperature load-bearing parts of hot blast stoves and the roof of acid open hearth furnaces. |

|||

Send inquiry

Please Leave your message you want to know! We will respond to your inquiry within 24 hours!