Product detail

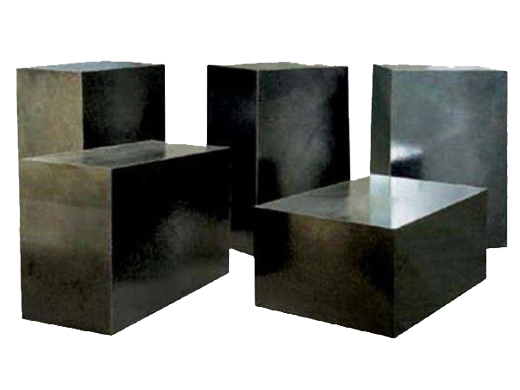

High Alumina Insulation Brick

Composition:SiO2 + Al2O3

Application:Insulation layer for various kinds of industrial furnaces

Capacity:500 tons per month

Color:Light grey or white or light yellow

Size:As your requirements

Raw Material:Bauxite & clay

Product Introduction

High alumina insulation brick refers to all lightweight bricks with AL2O3 more than 45%. It is made of bauxite and a small amount of clay. After grinding, it is poured into a slurry form by gas or foam. It burns at a temperature of 1300~1500℃. This kind of brick is not directly exposed to the high temperature in the kiln, but only has a thermal insulation layer near the kiln wall.

Features

1.High purity.

2.Good heat insulation.

3.High Strength.

4.Low Thermal Conductivity.

Application

High alumina insulation bricks are mainly used for heat insulation. In normal use, the kiln temperature is not directly contacted, and it is a kind of refractory brick product which is close to the furnace wall and has heat insulation and heat preservation effect. It can also be used in kilns with hydrogen, carbon monoxide and other gases as a protective atmosphere.

Product Parameters

| Item | High Aluminum Insulation Brick | |||

| LG-0.6 | LG-0.8 | LG-1.0 | LG-1.3 | |

| Al2O3% >= | 45 | 48 | 48 | 48 |

| Fe2O3% <= | 2.0 | 2.0 | 2.0 | 2.0 |

| Bulk Density(g/cm³) <= | 0.6 | 0.8 | 1.0 | 1.3 |

| Crushing Strength(Mpa) >= | 1.8 | 2.5 | 3.0 | 5.0 |

| Linear Change on Reheating 2% (℃*h) <= | 1200℃*12h | 1250℃*12h | 1300℃*12h | 1350℃*12h |

| Thermal Conductivity (w/m.k,{350±25℃}) <= | 0.25 | 0.32 | 0.45 | 0.55 |

| Max Service Temperature(℃) >= | 1250 | 1250 | 1300 | 1350 |

Send inquiry

Please Leave your message you want to know! We will respond to your inquiry within 24 hours!