Product detail

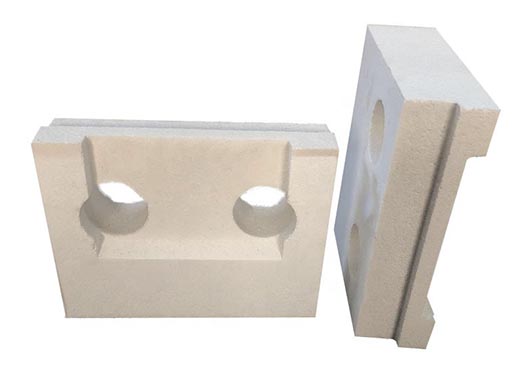

High Alumina Bricks for Hot Blast Furnace

Product introduction:

High alumina brick is a neutral refractory material with an alumina content of more than 48%. It is formed and calcined from bauxite or other raw materials with a high alumina content. It has high thermal stability and a refractoriness of more than 1770℃. It has good slag resistance and is used to build the lining of steelmaking electric furnaces, glass melting furnaces, cement rotary furnaces, etc.

High-load soft, low-creep high-alumina bricks are advanced refractory materials made of special-grade bauxite, fused corundum, and fused mullite as the main raw materials. This product has the advantages of small high-temperature creep, strong erosion resistance, and good thermal shock stability, and is suitable for large and medium-sized hot blast furnaces.

Application:

It is mainly used for building blast furnaces, hot blast furnaces, electric furnace roofs, blast furnaces, reverberatory furnaces, and rotary kiln linings. In addition, high-alumina bricks are also widely used as flat-hearth heat storage checker bricks, plugs for pouring systems, nozzle bricks, etc.

Product Parameters

| High alumina brick grades | Aluminum carbide (Al₂O₃) content |

| Special high alumina bricks | 75%<Al₂O₃≤85% |

| First-grade high alumina bricks | 70%<Al₂O₃≤75% |

| Second-grade high alumina bricks | 60%≤Al₂O₃<70% |

| Third-grade high alumina bricks | 48%<Al₂O₃<60% |

| Corundum bricks | Al₂O₃≥90% |

Send inquiry

Please Leave your message you want to know! We will respond to your inquiry within 24 hours!