Product detail

High Alumina Bricks for Cement Kiln

Product Introduction

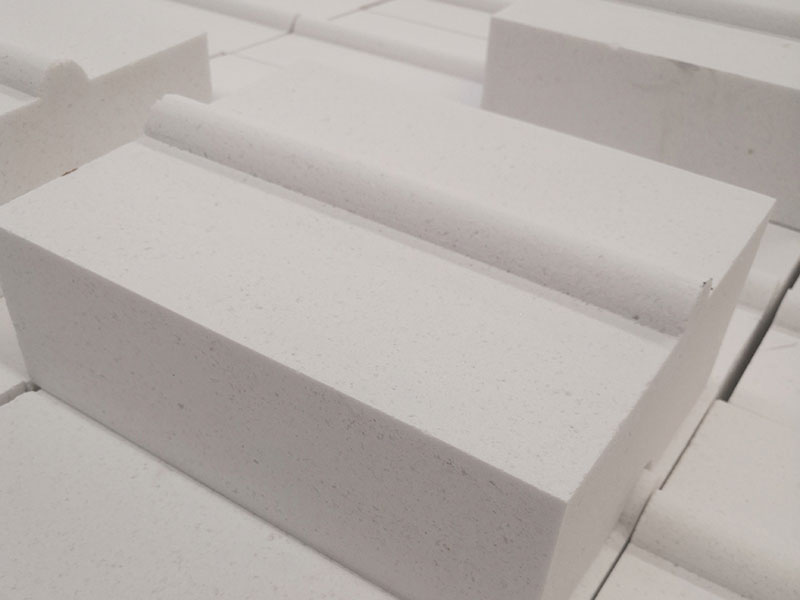

High alumina bricks designed for cement kilns are manufactured with high-quality raw materials. The bricks have a dense structure, which endows them with good resistance to abrasion and chemical corrosion. With a relatively high alumina content, they exhibit strong mechanical strength, ensuring stability and durability in the harsh environment of cement kilns.

Application

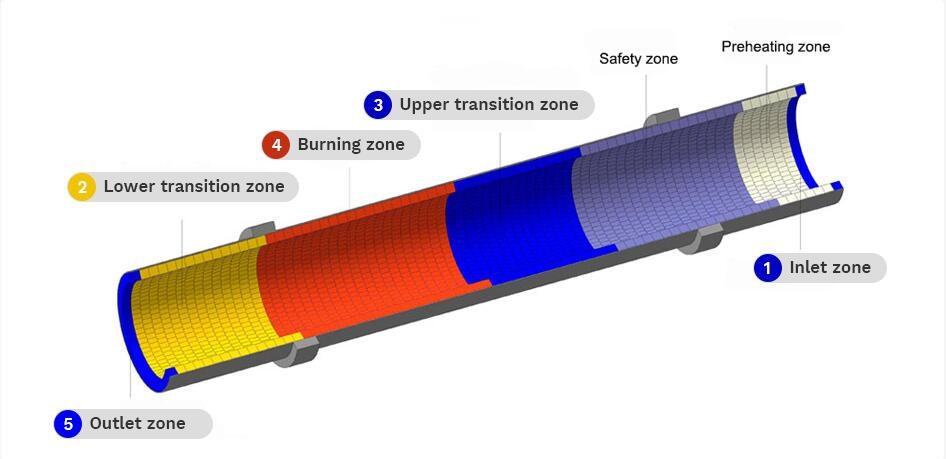

In cement kilns, high alumina bricks are widely used in various zones. In the preheating zone, they help to maintain the proper temperature gradient and resist the erosion caused by the flowing raw materials and gases. In the firing zone, where the temperature is extremely high and the chemical reactions are intense, these bricks play a crucial role in withstanding the thermal stress and the corrosive action of alkalis and other substances. Their reliable performance contributes to the efficient operation and extended service life of cement kilns, reducing maintenance frequency and costs, and thus enhancing the overall productivity and economic benefits of cement production.

Product Parameters

| High alumina brick grades | Aluminum carbide (Al₂O₃) content |

| Special high alumina bricks | 75%<Al₂O₃≤85% |

| First-grade high alumina bricks | 70%<Al₂O₃≤75% |

| Second-grade high alumina bricks | 60%≤Al₂O₃<70% |

| Third-grade high alumina bricks | 48%<Al₂O₃<60% |

| Corundum bricks | Al₂O₃≥90% |

Send inquiry

Please Leave your message you want to know! We will respond to your inquiry within 24 hours!