Product detail

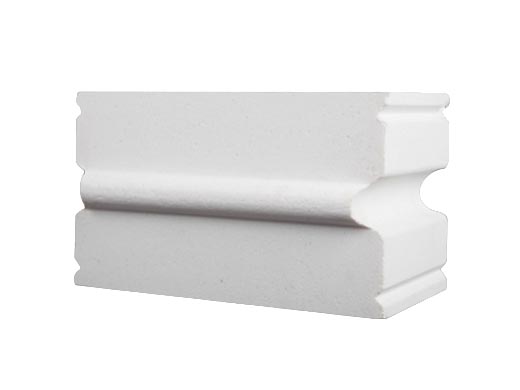

High Alumina Arc Brick

Product Introduction

Definition: It is generally made of bauxite clinker and a small amount of clay, and the Al₂O₃ content is usually above 65%2.

Manufacturing process: First, the raw materials such as high-alumina clinker are graded, sorted and screened to remove iron to ensure the purity and quality of the raw materials. Then the processed aggregates and binders are mixed in precise proportions and fully mixed to form a clay material with good plasticity. The clay is then made into the required brick shape and size using a high-pressure molding process, followed by drying to remove moisture, and finally fired in a high-temperature tunnel kiln, with the firing temperature generally between 1500℃ and 1600℃.

Performance characteristics:

High refractoriness: generally greater than 1790℃, and can remain stable for a long time in a high-temperature environment.

High load softening temperature: usually around 1550℃, and it is not easy to deform in a high-temperature environment under certain pressure.

Strong slag resistance: close to neutral refractory materials, can effectively resist the erosion of acidic slag and alkaline slag, but the ability to resist alkaline slag is slightly weaker than that of acidic slag.

High compressive strength: can withstand large external loads, not prone to cracking, damage, etc.

Good thermal shock stability: has a low thermal expansion coefficient, can better resist thermal shock stress, and is not prone to cracking3.

Application areas

Iron and steel industry: used in electric furnace covers, furnace tops and other parts, can withstand the erosion and scouring of high-temperature molten iron and slag.

Cement industry: as a lining material in cement kilns, it can resist the high-temperature calcination and chemical erosion of cement clinker.

Glass industry: suitable for key parts such as the wind and fire partition wall of the regenerator of glass kilns, and can withstand the erosion of high-temperature glass liquid and temperature changes.

Other fields: used as a lining material in some high-temperature chemical reactors, cracking furnaces and other chemical equipment, it can resist the erosion of high temperature, acid and alkali and other chemical substances.

Product Parameters

| Ingredients | Description |

| Alumina (Al₂O:) | Main component, the content is usually above 65%, which determines the key characteristics of high-alumina arc bricks such as refractory performance |

| Silicon dioxide (SiOz) | Exists as an auxiliary component, together with alumina, etc. to form a stable mineral phase structure, the content is generally around 10%-30% |

| Iron oxide (Fe₂O;) | It is an impurity component, but the content is usually low, generally around 1%-5%, too much will affect the performance of the brick |

| Other impurities | It may also contain a small amount of calcium oxide (Ca0), magnesium oxide (MgO), potassium oxide (K0), sodium oxide (Naz0), etc., the total amount is generally below 5% |

| Binder | Soft or semi-soft clay is usually used as a binder to enable the raw materials to be formed and ensure a certain strength, and the addition amount is generally around 5%-15% |

Send inquiry

Please Leave your message you want to know! We will respond to your inquiry within 24 hours!