Product detail

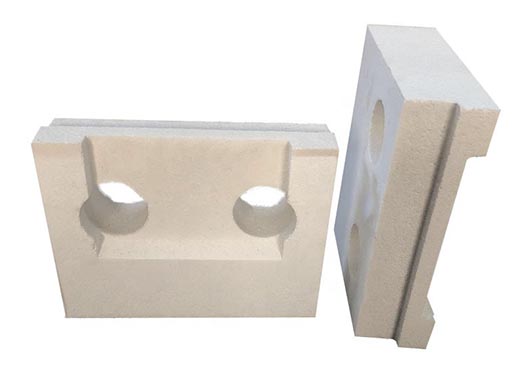

Fused Rebonded Magnesia Chrome Brick

Main Composition:MgO+CrO2

Application:Various kinds of industrial kiln

Capacity:500 tons per month

Application:Size : As your requirements

Refractoriness: >1790℃

Product Introduction

Fused rebonded magnesia-chrome bricks are made of fused magnesia-chrome particles as the main raw material, which is formed by high-pressure molding and ultra-high temperature sintering. The product has the characteristics of erosion resistance, and is mainly used for the working lining of the lower tank of the RH furnace and the alloy feeding port.

Features

1.High strength at high temperature.

2.Good volume stability.

3.Good corrosion and erosion resistance.

4.Good thermal shock resistance.

Application

It is suitable for secondary refining VOD furnace, LF furnace, VAD slag line, AOD furnace tuyere area, RH, DH vacuum degassing device, glass melting furnace regenerator, copper smelting converter tuyere area.

Product Parameters

| Item | Value | |||||||

| CNRMC12 | CNRMC14 | CNRMC16 | CNRMC18 | CNRMC20 | CNRMC22 | CNRMC26 | CNRMC30 | |

| MgO(%)>= | 70 | 68 | 65 | 60 | 60 | 55 | 50 | 45 |

| Cr2O3(%)>= | 12 | 14 | 16 | 18 | 20 | 22 | 26 | 30 |

| SiO2(%)<= | 2.0 | 1.8 | 1.8 | 1.5 | 1.5 | 1.5 | 1.5 | 1.5 |

| Apparent Porosity(%)<= | 16 | 16 | 16 | 15 | 15 | 15 | 15 | 15 |

| Cold Crushing Strength(Mpa)>= | 45 | 45 | 50 | 50 | 55 | 55 | 60 | 60 |

| Refractoriness Under Load(℃ 0.2Mpa)>= | 1700 | 1700 | 1700 | 1700 | 1700 | 1700 | 1700 | 1700 |

Send inquiry

Please Leave your message you want to know! We will respond to your inquiry within 24 hours!