Product detail

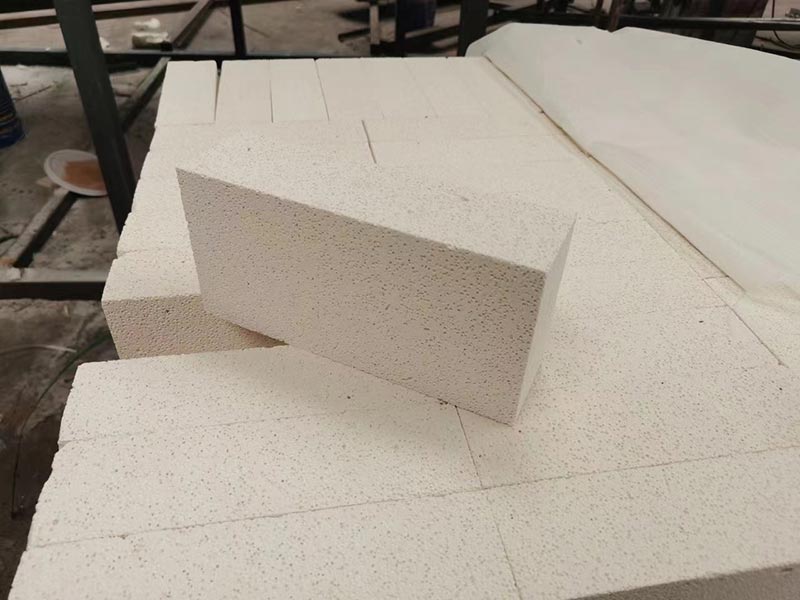

Fused Cast High Zirconia Bricks

Main Composition: zircon

Application: glass making industry

Capacity: 1000 tons per month

Application: Size : As your requirements

Package: On wooden pallets with plastic cover

Description of Fused Cast High Zirconia Brick

The series of HT-Fused cast high zirconia brick is fused cast high zirconia refractories which are specially designed refractory for glass furnace application. Fused cast high zirconia brick is made of artificial synthesis high purity raw materials through special casting process. The crystalline texture consists of baddeleyite and with the characteristics of excellent high temperature & corrosion resistance, low blister and stoning potential. These advantages can prevent liquid glass from pollution effectively.

Features of fused cast high zirconia brick

–Excellent high temperature & corrosion resistance

–Low blister and stoning potential

–High purity raw materials

–Wide application in glass industry,ceramic fiber industry and construction field,etc.

Application field of fused cast high zirconia brick

1.Fused cast high zirconia brick has wide application in a wide range of super high temperature furnaces and kilns in military industry,science research, high melting point Metallurgical, laser crystal and electronic,etc.

2.For high quality and special glass furnaces such as TV glass, Borosilicate glass, Alumina silicate glass, Halogen lighting glass, Opal glass and Fiber glass.

3.Fused cast high zirconia brick mainly consists of HT-Z88-WS and HT-Z95-WS, and are used in sidewall, throat cover, throat support, electrode brick, dam brick parts.

Product Parameters

| Item | TY-Z88-WS | TY-Z95-WS | ||

| Chemical Composition % | ZrO2 | >= | 89.00 | 93.60 |

| SiO2 | <= | 9.00 | 5.30 | |

| Al2O3 | <= | 1.00 | 1.00 | |

| Na2O | <= | 0.05 | 0.51 | |

| Others | <= | 1.60 | 1.0 | |

| Mineral Composition % | Baddeleyite | Typical | 89 | 94 |

| Glass Phase | 11 | 6 | ||

| Physical Properties | Cold Crushing Strength (MPa) | >= | 400 | 400 |

| Bulk Density (g/cm³) | Typical | 5.10 | 5.30 | |

| Liner Thermal Expansion (%) | 1000℃ | 0.65 | 0.70 | |

| 1500℃ | 0.10 | 0.30 | ||

Send inquiry

Please Leave your message you want to know! We will respond to your inquiry within 24 hours!