Product detail

Fireclay Bricks for Ladle

Product Introduction

Fireclay bricks for ladles are made from selected fireclay. They have a certain degree of plasticity and can be easily molded into various shapes and sizes required for ladle construction. These bricks have a relatively lower alumina content compared to high alumina bricks but still possess good refractory properties within a specific temperature range.

Application

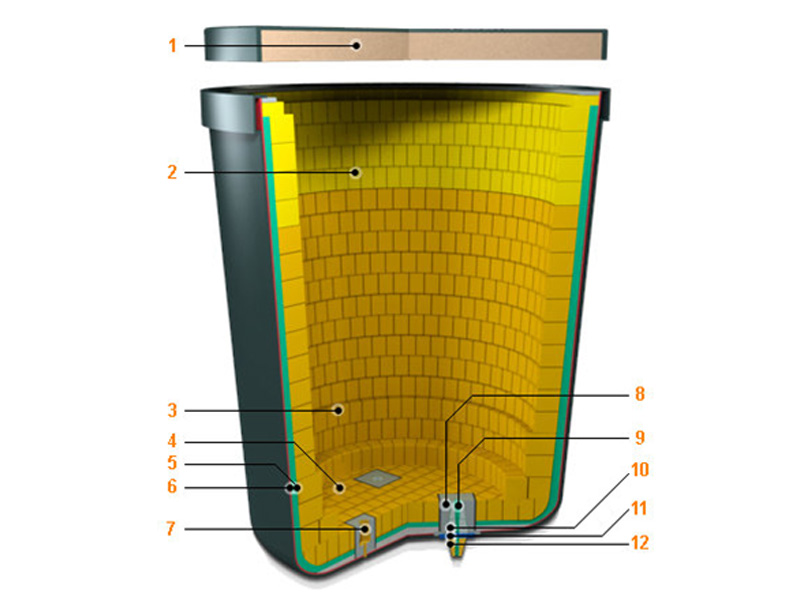

Fireclay bricks are mainly applied in the upper part and sidewalls of the ladle lining where the temperature and erosion intensity are relatively moderate. They play a role in heat insulation and provide an additional protective layer to the ladle, helping to maintain the temperature of the molten steel and reducing heat loss.

Advantages

– Good Thermal Shock Resistance: Can endure rapid temperature changes that occur during the filling and emptying of the ladle without significant cracking or damage, ensuring the durability of the lining.

– Cost-Effective: Compared to some high-end refractory materials, fireclay bricks offer a more economical choice while still meeting the basic refractory requirements of the ladle in certain areas, contributing to cost control in steelmaking operations.

Product Parameters

| Component | Content |

| Silica (SiO₂) | Approximately 50% – 60% |

| Alumina (Al₂O₃) | Around 20% – 30% |

| Iron Oxide (Fe₂O₃) | 3% – 8% |

| Other Minerals (such as Lime, Magnesia) | Remaining part |

Send inquiry

Please Leave your message you want to know! We will respond to your inquiry within 24 hours!