Product detail

Electric Furnaces

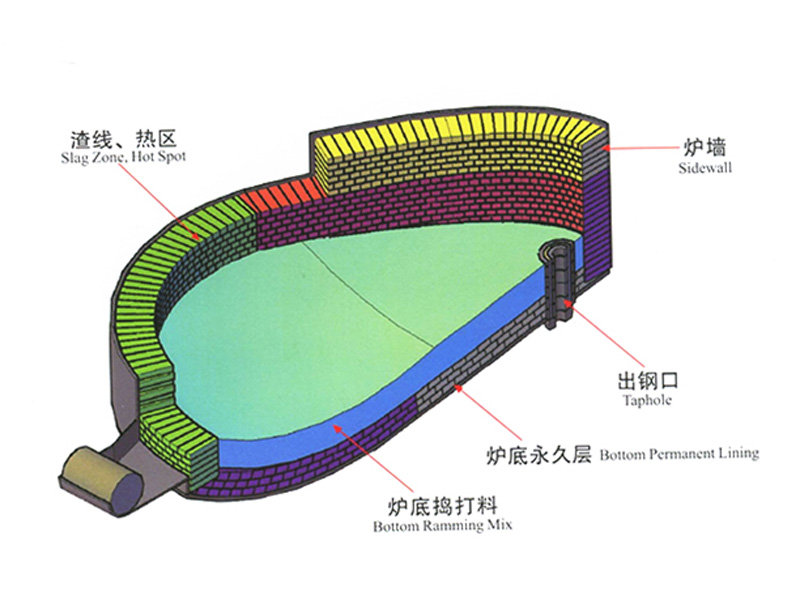

Magnesia-carbon bricks for the working layer of electric furnaces use large crystal high-purity fused magnesia and high-purity flake graphite as the main raw materials, combined with resin and added composite antioxidants, and formed by high pressure, with low porosity, high temperature strength, corrosion resistance and With the characteristics of strong anti-stripping ability, different grades of magnesia-carbon bricks can be selected for slag lines, hot spots and tapping holes according to smelting conditions.

Product Parameters

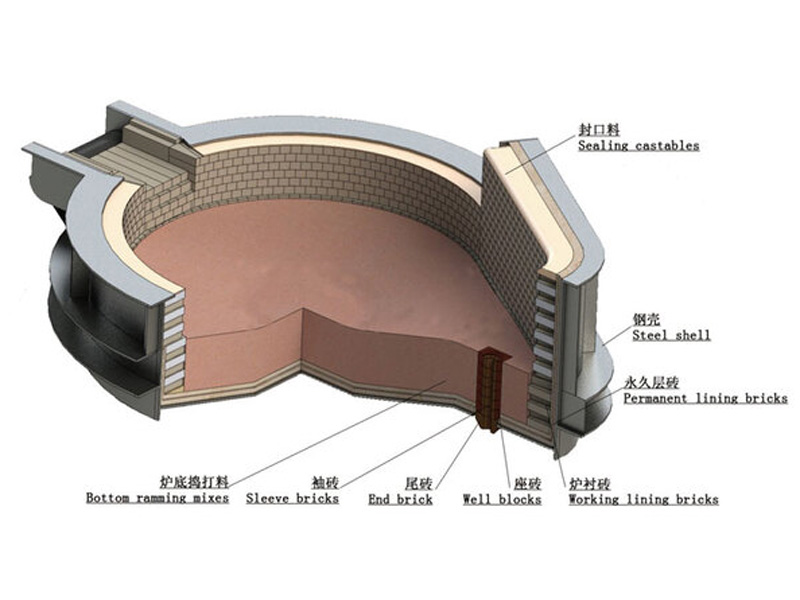

Magnesia bricks for BOF permanent lining have good performance for safety and thermal insulation.

| Item 项目 |

Magnesia bricks for EAF permanent lining 永久层镁砖 | |||

| MZ-93 | MZ-91 | MZ-89 | ||

| MgO % | ≥ | 93 | 91 | 89 |

| SiO2 % | ≤ | 3.5 | – | – |

| CaO % | ≤ | 2.0 | 3.0 | 3.0 |

| Apparent Porosity 显气孔率 % |

≤ | 18 | 18 | 20 |

| Bulk density 体积密度 (g/cm3) |

≥ | 2.95 | 2.9 | 2.86 |

| Cold Crushing Strength 常温耐压强度 (Mpa) |

≥ | 60 | 61 | 50 |

| Refractoriness under Load 0. 2MPa荷重软化开始温度,℃ |

≥ | 1620 | 1560 | 1550 |

| Reheating Linear Change Rate 加热永久线变化率 % |

(1650℃× 2h) | -0.4~0 | -0.5~0 | -0.6~0 |

Magnesia-carbon bricks for the working layer of electric furnaces use large crystal high-purity fused magnesia and high-purity flake graphite as the main raw materials, combined with resin and added composite antioxidants, and formed by high pressure, with low porosity, high temperature strength, corrosion resistance and With the characteristics of strong anti-stripping ability, different grades of magnesia-carbon bricks can be selected for slag lines, hot spots and tapping holes according to smelting conditions.

| Item 项目 |

Magnesia carbon bricks 镁碳砖 |

||||

| MT-14A | MT-14B | MT-10A | MT-5A | ||

| MgO % | ≥ | 76 | 74 | 80 | 85 |

| C % | ≥ | 14 | 14 | 10 | 5 |

| Apparent Porosity 显气孔率 % |

≤ | 4 | 5 | 4 | 6 |

| Bulk density 体积密度 (g/cm3) |

≥ | 2.95 | 2.9 | 2.95 | 2.95 |

| Cold Crushing Strength 常温耐压强度 (Mpa) |

≥ | 40 | 35 | 40 | 30 |

| High Temperature Flexural Strength 高温抗折强度(Mpa) |

≥ | 14 | 12 | 60 | 6 |

| (1400℃ , 30min) | |||||

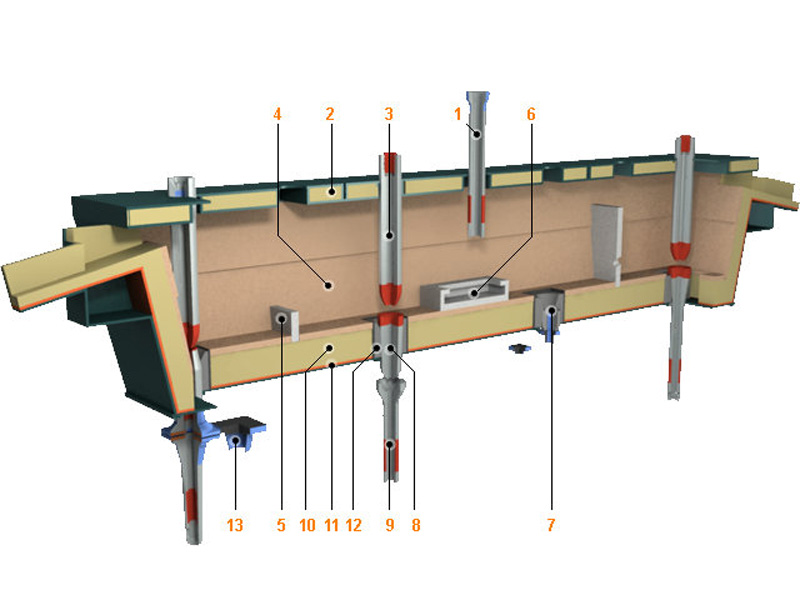

This series of products is made from high quality magnesite and high-purity flake graphite as raw materials by high-pressure pressing or isostatic shaping. we can supply whole or splitted taphole sets. These products have the features of low porosity, high strength, excellent slag erosion and excellent thermal shock resistance, and long service life.

Maded from high-quality magnesite, the mortar performs well in use with excellent workability, desirable.

| Item 项目 |

Mortar 砌筑⽕泥 |

|

| DHN | ||

| Al2O3 % | ≥ | 90 |

| Grain size 粒度,mm |

– | 0-0.2 |

| Hardening time 粘结时间, sec |

– | 60~180 |

| Adhesive strength 粘结强度, Mpa |

≥ | 1 |

These products are made from high quality magnesite and MgO-CaO-Fe2O3 clinker show excellent resistance against steel penetration, superior erosion resistance, easily-sintering, high bulk density and can be easy installed. The products are ideal choice for bottom lining of furnaces with HP/UHP modes.

| Item 项目 |

Dry ramming masses for EAF bottom 炉底⼲式捣打料 |

||||

| DLD 85 | DLD80 | DLD68 | |||

| MgO % | ≥ | 85 | 80 | 68 | |

| CaO % | – | 6-8 | 6-9 | 18-25 | |

| Fe2O3 % | – | 4-5 | 5-9 | 3-5 | |

| SiO2 % | ≤ | 1.5 | 1.5 | 1.5 | |

| Bulk density 体积密度 (g/cm3) |

(1600℃, 3h) | ≥ | 2.45 | 2.45 | 2.45 |

| Cold Crushing Strength 常温耐压强度 (Mpa) |

(1300℃, 3h) | ≥ | 10 | 10 | 10 |

| (1600℃, 3h) | ≥ | 30 | 30 | 30 | |

These products are made by steel fibre reinforced ultra-low cement castables. Main raw materials are corundum, spinel and mullite. Product characterizes by high strength, good thermal shock and erosion resistance, long service life.

| Item 项目 |

Precast blocks for EAF roof 预制件 |

|||||

| DSY80 | DSY85 | DSY90 | DSY92 | |||

| (Al2O3+MgO) % | ≥ | 80 | 85 | 90 | 90 | |

| Cr2O3 % | ≥ | – | – | 2 | – | |

| Bulk density 体积密度 (g/cm3) |

(110℃, 24h) | ≥ | 2.75 | 2.9 | 3.05 | 3.05 |

| Cold Crushing Strength 常温耐压强度 (Mpa) |

(110℃, 24h) | ≥ | 40 | 40 | 40 | 40 |

| (1500℃.3h) | ≥ | 60 | 60 | 60 | 60 | |

| Reheating Linear Change Rate 加热永久线变化率 % |

(1500℃.3h) | 士 | 0.5 | 0.5 | 0.5 | 0.5 |

These products are produced by mixing magnesite, forsterite and silica as the main materials. They show the features of easy installation, floating resistance, high self-open rate and good safety.

| Item 项目 |

Filling Sand for EAF taphole 出钢⼝填料 |

|||

| DCT-90 | DCT-75 | DCT-25 | ||

| MgO % | ≥ | – | 10 | 55 |

| SiO2 % | ≥ | 90~95 | 75 | 25 |

| Fe2O3, % | – | – | – | 3-8 |

| Grain size 粒度,mm |

– | 2-6 | 2-6 | 2-6 |

We can provide monocast taphole spout block and Al2O3-SiC-C taphole 2-3 spout block. These products have good erosion resistance and thermal shock resistance, long service life ect.

| Item 项目 |

Precast block for taphole spout 出钢槽预制件 |

||

| DCAMT-80 | DCY-85 | ||

| (MgO+Al2O3), % | ≥ | 80 | – |

| Al2O3 % | ≥ | – | 85 |

| (C+SiC), % | ≥ | 8 | – |

| Bulk density 体积密度 (g/cm3) |

≥ | 2.8 | 2.8 |

| Cold Crushing Strength 常温耐压强度 (Mpa) |

≥ | 35 | 40 |

Using high quality magnesia and complex binders for gunning mixes for EAF. Product has high adhesive strength, low rebound rate, good sintering, good erosion resistance, and can be used as cold or hot repair materials at slag line and sidewall.

| Item 项目 |

Gunning mixes for EAF 喷补料 |

||||

| SH-DPB-87 | SH-DPB-75 | SH-DPB-65 | |||

| MgO/, % | ≥ | 87 | 75 | 65 | |

| CaO, % | ≤ | – | 10 | 30 | |

| Bulk density 体积密度 (g/cm3) |

≥ | 2.6 | 2.4 | 2.3 | |

| Cold Crushing Strength 常温耐压强度 (Mpa) |

(110℃, 24h) | ≥ | 15 | 15 | 15 |

| (1500℃, 3h) | ≥ | 25 | 25 | 25 | |

| Reheating Linear Change Rate 加热永久线变化率 % |

(1500℃, 3h) | – | -1.5-0 | -1.5-0 | -1.5-0 |

We can supply carbon contained and carbon free repairing mixes with good flow ability,good adhesion and long service life. Compared with the carbon containing repairing mixes, carbon free repairing mixes have less environmental impact, shorter sintering time and better flow ability.

| Item 项目 |

Repairing mixes 热修补料 |

||||||

| DDB-78 | DDB-65 | DDB-85 | DCX-78 | DCX-92 | |||

| Quality 材质 | – | MgO-C series 镁碳质 |

MgO series 镁质 |

MgO-C series镁碳质 | MgO series镁质 | ||

| MgO % | ≥ | 78 | 65 | 85 | 78 | 92 | |

| C % | – | 5-7 | 5-7 | – | 5-7 | – | |

| Bulk density 体积密度 (g/cm3) |

(800℃, 0.5h) | ≥ | 2.2 | 2.2 | 2.4 | 2.2 | 2.6 |

Send inquiry

Please Leave your message you want to know! We will respond to your inquiry within 24 hours!