Product detail

Corundum Bricks

Corundum brick refers to refractory products with alumina content greater than 90% and corundum as the main crystalline phase. Very high temperature compressive strength (up to 340MPa). High initial softening temperature under load (> 1700℃). Good chemical stability, strong resistance to acid or alkaline slag, metal and glass liquid. The stability of thermal shock is related to its structure. The corrosion resistance of compact products is good, but the stability of thermal shock is poor. It is divided into sintered corundum brick and fused alumina brick. Sintered alumina and fused corundum can be used respectively as raw materials or alumina clinker with high Al2O3/SiO2 ratio and sintered alumina. Unburned corundum bricks can also be made from phosphoric acid or other adhesives. It is mainly used in blast furnace and blast furnace hot blast furnace, steel furnace outside finishing furnace, sliding water, glass melting furnace and petrochemical industry furnace.

Corundum brick has been widely used in high temperature and high pressure, severe chemical erosion and mechanical wear of petrochemical thermal lining material, with the progress of petrochemical industry production technology, a lot of new technology and new technology is adopted in production, in order to make equipment to large load, long cycle, low energy consumption, low cost, except to modify all sorts of thermal equipment, also for a variety of thermal equipment lining materials is put forward higher requirements. Therefore, a series of chromium corundum products with better high temperature resistance and erosion resistance were developed to meet the needs of petrochemical industry.

White corundum hardness is slightly higher than brown corundum, toughness is slightly lower, high purity, good self-sharpening, strong grinding ability, low calorific value, high efficiency, acid and alkali corrosion resistance, high temperature resistance and thermal stability.Made of white corundum sand abrasive tools, suitable for grinding high carbon steel, high speed steel and stainless steel and other fine grain abrasives, white corundum can also be used for precision casting and senior refractory materials.

White corundum brick has the characteristics of high refractoriness, good thermal shock stability, high high temperature strength, excellent corrosion resistance, strong slag resistance, small expansion coefficient, low creep property, anti-peeling and so on. It is suitable for the use of high temperature kiln under various atmosphere conditions.High quality high purity corundum brick is widely used in high temperature sintering of zirconia ceramics, fluorescent materials, electronic ceramics, magnetic materials, ceramic powders, gasifier in petrochemical industry, second-stage reformer for synthetic ammonia, carbon black reaction furnace and high temperature kiln furnace in glass industry, etc.The appearance size, physical and chemical indexes and service life of the products have reached or exceeded the level of similar products at home and abroad.

White corundum brick has the characteristics of high refractoriness, good thermal shock stability, high high temperature strength, excellent corrosion resistance, strong slag resistance, small expansion coefficient, low creep property, anti-peeling and so on. It is suitable for the use of high temperature kiln under various atmosphere conditions.High quality high purity corundum brick is widely used in high temperature sintering of zirconia ceramics, fluorescent materials, electronic ceramics, magnetic materials, ceramic powders, gasifier in petrochemical industry, second-stage reformer for synthetic ammonia, carbon black reaction furnace and high temperature kiln furnace in glass industry, etc.The appearance size, physical and chemical indexes and service life of the products have reached or exceeded the level of similar products at home and abroad.

Composition: alumina content greater than 90% and corundum

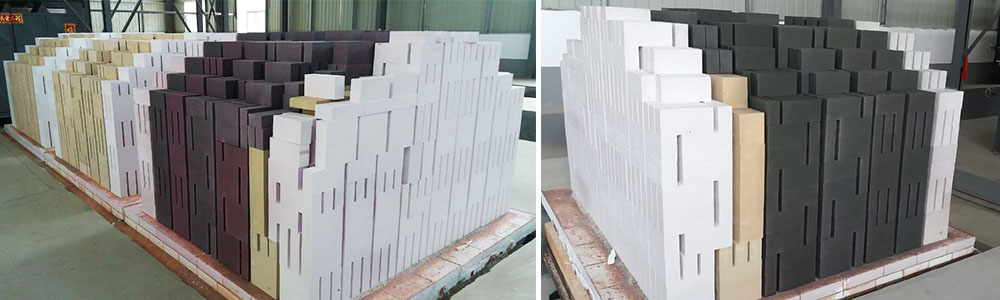

Color: White

Standard Size: 230*114*65 mm

Product Parameters

|

Items

|

Corundum Bricks | ||

| GY-97 | BF-90XD | BF-90ZG | |

| Al2O3 % | ≥97 | ≥90 | ≥90 |

| Fe2O3 % | ≤0.3 | ≤0.3 | ≤1.0 |

| Cold Crushing Strength | ≥60 | ≥60 | ≥100 |

| Apparent Porosity | ≤21 | ≤17 | ≤14 |

| Refractoriness under Lord 0.2MP | ≥1700 | ≥1700 | ≥1650 |

| Usage | Furnace Shaft , Furnace bosh ,Furnace belly | ||

Send inquiry

Please Leave your message you want to know! We will respond to your inquiry within 24 hours!