Product detail

Corundum bricks for cement kiln

Product Introduction

Performance characteristics: It has the advantages of high strength, high hardness, wear resistance, high temperature resistance, erosion resistance, low thermal conductivity, etc. It can effectively protect the kiln, reduce heat emission, and improve heat utilization efficiency.

Preparation process: There are sintering, electric melting and other preparation methods. The raw materials are crushed, screened, mixed, and formed, and then fired at high temperature.

Application

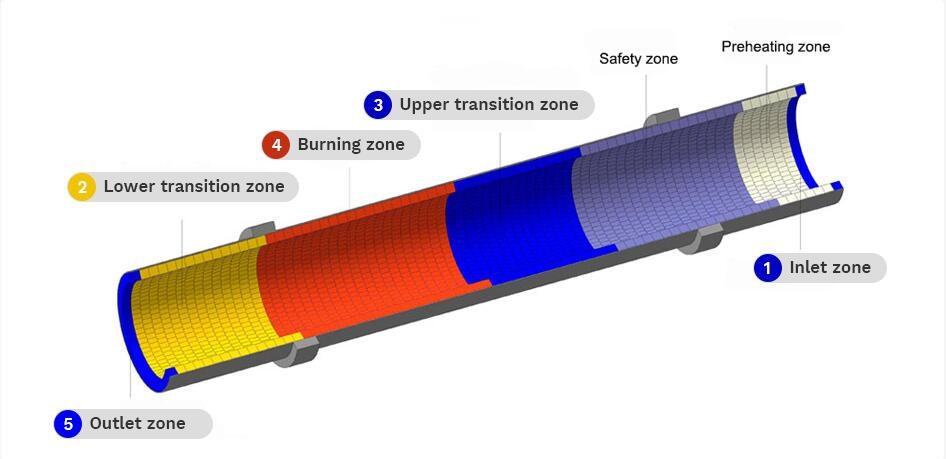

Corundum bricks for cement kilns play a vital role in the cement production process, and their application is mainly concentrated in the key parts of cement kilns. In the transition zone of the cement kiln, the temperature changes frequently and the chemical reaction of the materials is violent. Corundum bricks can withstand frequent temperature fluctuations with their excellent high temperature resistance and thermal shock resistance. It can effectively resist the erosion and wear of materials, ensure the stability of the lining structure of the transition zone, and provide reliable guarantee for the smooth formation of cement clinker.

In the cooling zone, the high thermal conductivity and good wear resistance of corundum bricks are fully utilized. It can quickly transfer heat, accelerate the cooling process of cement clinker, and improve the quality and production efficiency of cement. At the same time, its wear resistance can resist the scouring and friction of the kiln lining caused by the clinker during the cooling process, reduce the loss of the kiln lining, and extend the service life of the cooling belt, thereby ensuring the stable and efficient operation of the entire cement kiln, reducing production costs, and improving the company’s economic benefits and market competitiveness. It plays an indispensable role in modern cement industry production.

Product Parameters

| Ingredients | Content range |

| Al₂O₃ | ≥90% |

| SiO₂ | Small amount |

| Na₂O | Small amount |

| Other impurities | Trace amount |

Send inquiry

Please Leave your message you want to know! We will respond to your inquiry within 24 hours!