Product detail

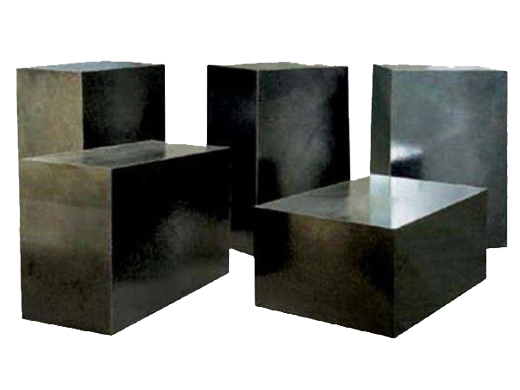

Clay Insulation Brick

Main Composition:SiO2 + Al2O3

Application:Insulation layer for various kinds of industrial furnaces

Raw Material:Chamotte

Color:Yellow

Standard Size:230*114*65 mm

Long time working temperature:1000℃-1200℃

Package:Export wooden pallets

Product Introduction

Fireclay insulation brick is made of local top grade fireclay materials with a content of 35%~42% Al2O3 according to the lasted national standard. The working temperature of them is from 1000-1200 ℃ and bulk density is 0.5-1.0 g/cm3.

Features

1.Low thermal conductivity.

2.Excellent insulating property.

3.Steady quality.

4.Low impurities.

Application

Clay insulation bricks have a wide range of uses, mainly used in thermal boilers, glass furnaces, cement furnaces, fertilizer gas furnaces, blast furnaces, hot blast furnaces, coking furnaces, electric furnaces, etc.

Product Parameters

| Item | Clay Insulation Brick | |||

| NG-0.5 | NG-0.6 | NG-0.8 | NG-1.0 | |

| Al2O3% >= | 35 | 40 | 42 | 42 |

| Fe2O3% <= | 2.5 | 2.5 | 2.0 | 2.0 |

| Bulk Density (g/cm3) <= | 0.5 | 0.6 | 0.8 | 1.0 |

| Cold Crushing Strength(Mpa) >= | 1.0 | 1.5 | 2.0 | 2.5 |

| Linear Change On Reheating2% (℃*h) <= | 1000℃*12h | 1150℃*12h | 1200℃*12h | 1200℃*12h |

| Thermal Conductivity(w/m.k,{350±25℃}) <= | 0.18 | 0.25 | 0.35 | 0.5 |

| Maximum Use Temperature (℃) >= | 1000 | 1100 | 1150 | 1200 |

Send inquiry

Please Leave your message you want to know! We will respond to your inquiry within 24 hours!