Product detail

Clay bricks for CFB Boiler

Product Introduction

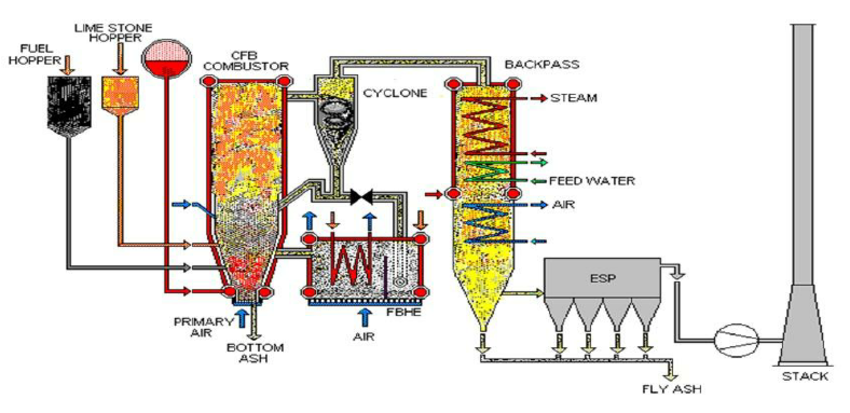

Clay bricks for circulating fluidized bed boilers are specially designed for the special working conditions of circulating fluidized bed boilers and are weakly acidic refractory products. With its good thermal properties and moderate cost, it plays a key role in many parts of the boiler. This kind of clay brick has good resistance to rapid cooling and heating, can withstand the frequent temperature fluctuations during the operation of the circulating fluidized bed boiler, and is not easy to break due to thermal stress. At the same time, it has a certain resistance to acidic slag and acidic gas, which can effectively extend the service life.

Application

Boiler outer wall: As the outer layer protection of the boiler, clay bricks can resist the influence of external environmental factors on the boiler, and at the same time play a certain role in heat preservation, reduce heat loss to the outside world, and improve the thermal efficiency of the boiler.

Low-temperature flue: In the low-temperature flue, clay bricks can withstand the scouring of flue gas and a certain degree of acid corrosion, ensure the structural integrity of the flue, and ensure the smooth discharge of flue gas.

Product Parameters

| Component | Content |

| Silica (SiO₂) | Approximately 50% – 60% |

| Alumina (Al₂O₃) | Around 20% – 30% |

| Iron Oxide (Fe₂O₃) | 3% – 8% |

| Other Minerals (such as Lime, Magnesia) | Remaining part |

Send inquiry

Please Leave your message you want to know! We will respond to your inquiry within 24 hours!