Product detail

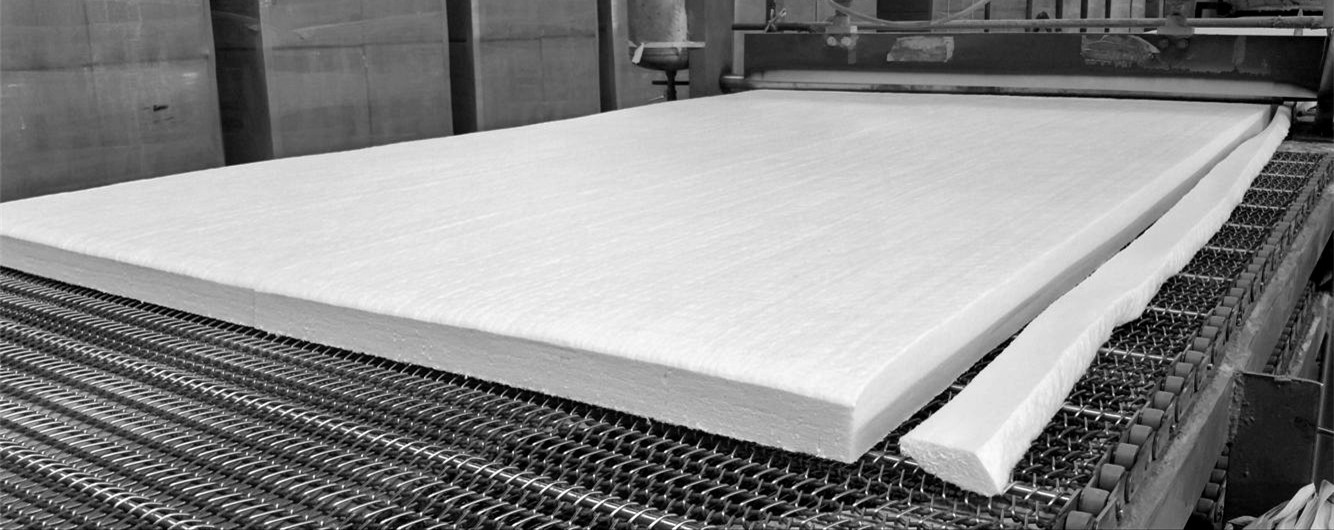

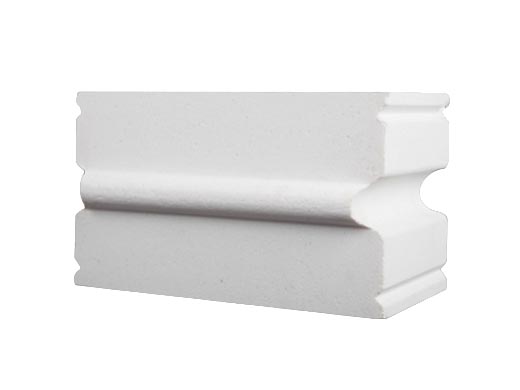

Ceramic Fibre Blanket

Ceramic Fibre Blanket is composed of long flexible, interwoven fibers manufactured by the “spun” process yielding a strong,lightweight, durable product. This material can be used for applications with temperatures from 1000°F (538°C) to 2600°F (1425°C).The product is firm, light and durable.Thermal and physical properties are retained after drying following wetting by oil, steam or water. This ceramic fibre blanket products are completely inorganic, so there are no fumes when heating for the first time. Hong Tai ceramic fibre blanket has higher tensile strength and longer service life.

Features of Ceramic Fibre Blanket

*Excellent thermal shock resistance

*Excellent heat insulation

*Excellent thermal stability

*Excellent Shock and chemical attack resistant

*High tensile strength

*Excellent chemical stability

*Low thermal conductivity

*Low heat storage

*Excellent thermal insulation,fireproof and sound absorption

Applications of Ceramic Fibre Blanket

1.Ceramic industry:

Kiln car insulation and seals,

Continuous and batch kilns

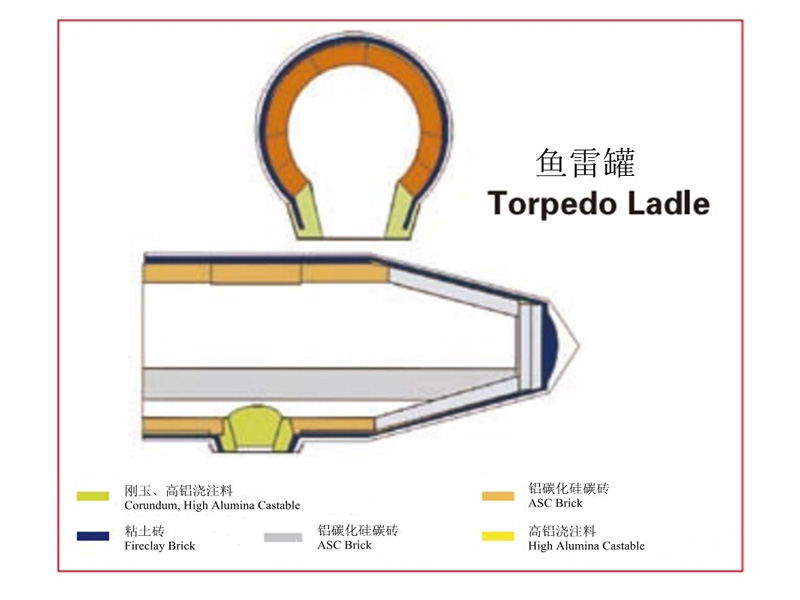

2.Steel industry:

Heat treating and annealing furnaces,

Furnace door linings and seals,

Soaking pit covers and seals,

Furnace hot face repairs,

Reheating furnace and ladle covers

3.Refining and petrochemical industry:

Reformer and pyrolysis lining,

Tube seals,gaskets and expansion joints,

High temperature pipe,duct and turbine insulation

Crude oil heater linings

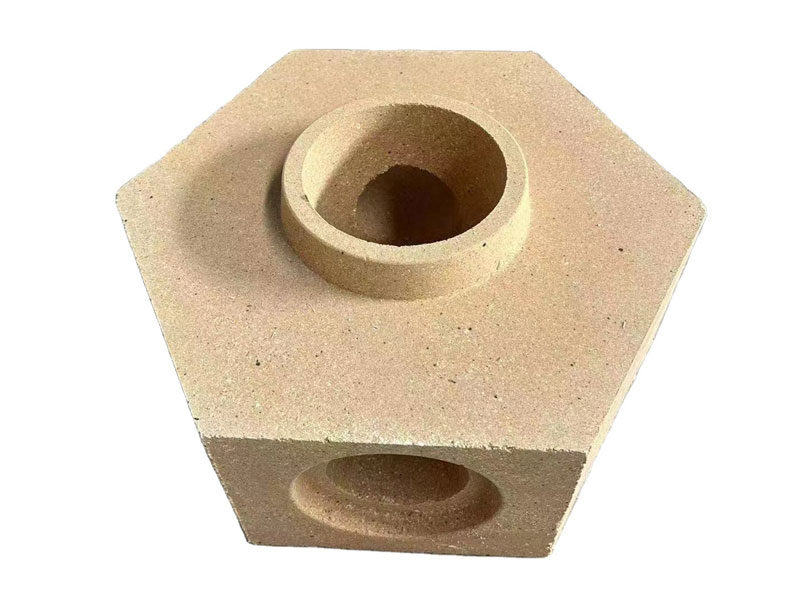

4.Other typical application:

* Industry furnace wall lining *Back lining material *Fire prevention

*High-temperature tube heat insulation material *Module/folding block processing material

*Filling and sealing material in high temperature environment.

*Sound-absorbing or high temperature filtration materials.

Product Parameters

|

Description

|

STD BLANKET

|

HP BLANKET

|

HA BLANKET

|

HZ BLANKET

|

|||||

|

Classification Temperature (℃ )

|

1260

|

1260

|

1350

|

1430

|

|||||

|

Chemical Composition (%)

|

|||||||||

|

Al2O3

|

≥43

|

≥44

|

≥52

|

≥35

|

|||||

|

SiO2

|

≥54

|

≥55

|

≥47

|

≥49

|

|||||

|

ZrO2

|

–

|

–

|

–

|

≥15

|

|||||

|

Color

|

White

|

White

|

White

|

White

|

|||||

|

Shot Content (%)

|

≤15

|

≤15

|

≤15

|

≤12

|

|||||

|

Density (kg/m³)

|

64

|

96

|

128

|

96

|

128

|

96

|

128

|

96

|

128

|

|

Tensile Strength (kPa)

|

30

|

50

|

70

|

50

|

70

|

50

|

70

|

50

|

70

|

|

Permanent Linear Shrinkage (%)

|

1000℃ x 24h ≤2.5

|

1100℃ x 24h ≤2.5

|

1200℃ x 24h ≤3.0

|

1350℃ x 24h ≤3.0

|

|||||

|

Thermal Conductivity (W/m·K)

|

|||||||||

|

200℃

|

0.07

|

0.06

|

0.06

|

0.06

|

0.06

|

0.06

|

0.06

|

0.06

|

0.06

|

|

400℃

|

0.12

|

0.11

|

0.10

|

0.11

|

0.10

|

0.11

|

0.10

|

0.11

|

0.10

|

|

600℃

|

0.20

|

0.19

|

0.18

|

0.19

|

0.17

|

0.18

|

0.16

|

0.16

|

0.15

|

|

800℃

|

0.30

|

0.23

|

0.20

|

0.23

|

0.20

|

0.22

|

0.20

|

0.21

|

0.19

|

|

1000℃

|

0.40

|

0.32

|

0.27

|

0.31

|

0.26

|

0.30

|

0.26

|

0.30

|

0.26

|

Send inquiry

Please Leave your message you want to know! We will respond to your inquiry within 24 hours!