Product detail

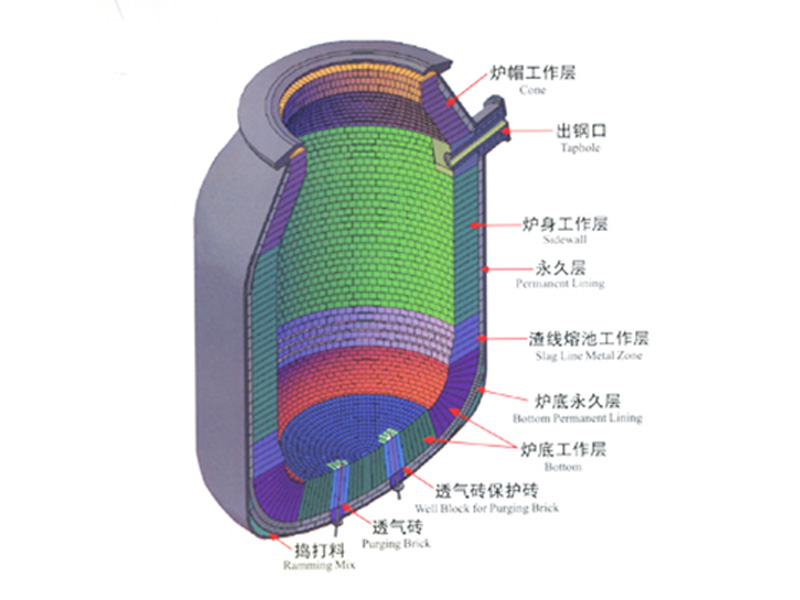

BOF

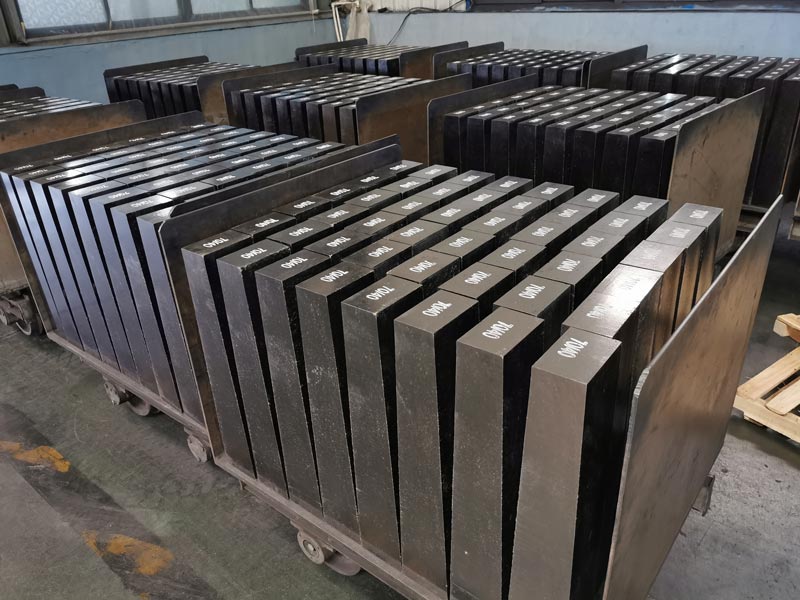

Magnesia-carbon bricks use large crystal high-purity fused magnesia and high-purity flake graphite as the main raw materials. They are combined with resin and added with composite antioxidants. After high-pressure molding, they have the characteristics of low porosity, high temperature strength, corrosion resistance and peeling resistance. According to the smelting conditions, different grades of magnesia carbon bricks can be selected for the slag line, impact zone, trunnion and other parts.

Product Parameters

Magnesia bricks for BOF permanent lining have good performance for safety and thermal insulation.

| Item 项目 |

Magnesia bricks 镁砖 |

|||

| MZ-93 | MZ-91 | MZ-89 | ||

| MgO % | ≥ | 93 | 91 | 89 |

| SiO % | ≤ | 3.5 | – | – |

| CaO % | ≤ | 2 | 3 | 3 |

| Apparent Porosity 显气孔率 % |

≤ | 18 | 18 | 20 |

| Bulk density 体积密度 (g/cm3) |

≥ | 2.95 | 2.9 | 2.85 |

| Cold Crushing Strength 常温耐压强度 (Mpa) |

≥ | 60 | 60 | 50 |

| Refractoriness under Load 0. 2MPa荷重软化开始温度,℃ |

≥ | 1620 | 1560 | 1550 |

| Reheating Linear Change Rate 加热永久线变化率 % |

(1650℃× 2h) | -0.4~0 | -0.5~0 | -0.6~0 |

Magnesia-carbon bricks use large crystal high-purity fused magnesia and high-purity flake graphite as the main raw materials. They are combined with resin and added with composite antioxidants. After high-pressure molding, they have the characteristics of low porosity, high temperature strength, corrosion resistance and peeling resistance. According to the smelting conditions, different grades of magnesia carbon bricks can be selected for the slag line, impact zone, trunnion and other parts.

| Item 项目 |

Magnesia carbon bricks 镁碳砖 |

|||||

| MT-18A | MT-14A | MT-14B | MT-10A | |||

| MgO % | ≥ | 72 | 76 | 74 | 80 | |

| C % | ≥ | 18 | 14 | 14 | 10 | |

| Apparent Porosity 显气孔率 % |

≤ | 3 | 4 | 5 | 4 | |

| Bulk density 体积密度 (g/cm3) |

≥ | 2.9 | 2.95 | 2.9 | 2.95 | |

| Cold Crushing Strength 常温耐压强度 (Mpa) |

≥ | 35 | 40 | 35 | 40 | |

| High Temperature Flexural Strength 高温抗折强度(Mpa) |

(1400℃ , 30min) | ≥ | 12 | 14 | 12 | 6 |

This series of products is made from high quality magnesite and high-purity flake graphite, by high-pressure pressing or isostatic shaping. we can supply whole or splitted taphole sets. These products have the features of low porosity, high strength, excellent slag erosion and excellent thermal shock resistance, and long service life.

| Item 项目 |

Taphole sets 出钢⼝砖 |

||

| ZLC14 | ZLC10 | ||

| MgO % | ≥ | 78 | 82 |

| C % | ≥ | 14 | 10 |

| Apparent Porosity 显气孔率 % |

≤ | 5 | 5 |

| Bulk density 体积密度 (g/cm3) |

≥ | 85 | 90 |

| Cold Crushing Strength 常温耐压强度 (Mpa) |

≥ | 50 | 50 |

| High Temperature Flexural Strength 高温抗折强度(Mpa) |

≥ | 12 (1450℃,20min) |

10 (1450℃,30min) |

Using high-quality magnesia as the main raw material and adding chemical binders, it has good construction performance and bonding strength, and can effectively resist the erosion and penetration of high-temperature molten steel.

| Item 项目 |

ZHN | |

| Mortar 砌筑⽕泥 |

||

| (MgO+ Al2O3), % | ≥ | 94.5 |

| Grain size 粒度,mm |

– | 0-0.2 |

| Hardening time 粘结时间, sec |

– | 60~180 |

| Adhesive strength 粘结强度, Mpa |

≥ | 1 |

These products are made from high quality magnesite and bonded by chemical binders, and show features of easy installation, high strength, and excellent resistance against steel penetration and erosion.

| Item 项目 |

Dry ramming mixes 捣打料 |

||||

| ZLD92 | ZLD90 | ZLD88 | |||

| MgO % | ≥ | 92 | 90 | – | |

| (MgO+Cr2O3) % | ≥ | – | – | 88 | |

| C % | ≥ | – | 5 | – | |

| Bulk density 体积密度 (g/cm3) |

≥ | 2.7 | 2.3 | 2.6 | |

| Cold Crushing Strength 常温耐压强度 (Mpa) |

(110℃, 24h) | ≥ | 20 | 15 | 25 |

| (1500℃, 3h) | ≥ | 20 | 15 | 15 | |

| Application 使用范围 |

Bottom, cover and tappinghole 炉底、炉帽、出钢捣打料 |

||||

Different density and shapes of slag balls/plugs have been implemented according to different conditions to achieve the purpose total prevention of slag outgoing.

| Item 项目 |

Slag stopping ball 挡渣球 |

Slag stopping plug 挡渣塞 |

||

| DZQ | DZS | |||

| Plug head 塞头部分 |

Plug rod 塞杆部分 |

|||

| (Al2O3 +SiO2 +Fe2O3), % | ≥ | 80 | 85 | 78 |

| Bulk density 体积密度 (g/cm3) |

≥ | 4 | 3.5 | 2.6 |

| Cold Crushing Strength 常温耐压强度 (Mpa) |

≥ | 20 | 45 | 30 |

We are using high quality magnesia, doloma and complex binders to produce the series of gunning mixes for BOF with high adhesive strength, low rebound rate, good sintering, good erosion resistance, which can be used at slag line and trunnion.

| Item 项目 |

Gunning mixes 喷补料 |

||||

| ZPB-85 | ZPB-75 | ZPB-65 | |||

| MgO % | ≥ | 85 | 75 | 65 | |

| CaO % | ≤ | – | 10 | 20 | |

| Bulk density 体积密度 (g/cm3) |

≥ | 2.4 | 2.4 | 2.3 | |

| Cold Crushing Strength 常温耐压强度 (Mpa) |

(110℃, 24h) | ≥ | 15 | 15 | 25 |

| (1500℃, 3h) | ≥ | 20 | 20 | 20 | |

| Reheating Linear Change Rate 加热永久线变化率 % |

(1500℃, 3h) | -2.0~0 | -2.5~0 | -3.0~0 | |

We can supply carbon contained and carbon free repairing mixes repairing mixes with good flow ability, good adhesion and long service life. Compared with the carbon containing repairing mixes, carbon free repairing mixes have less environmental impact, shorter sintering time and better flow ability.

| Item 项目 |

Repairing mixes 补炉料 |

||||||

| ZDB-78 | ZDB-65 | ZDB-85 | ZCX-78 | ZCX-92 | |||

| Quality 材质 | – | MgO-C series 镁碳质 |

MgO series 镁质 |

MgO-C series镁碳质 | MgO series镁质 | ||

| MgO % | ≥ | 78 | 65 | 85 | 78 | 92 | |

| C % | – | 5-7 | 5-7 | – | 5-7 | – | |

| Bulk density 体积密度 (g/cm3) |

(800℃, 0.5h) | ≥ | 2.2 | 2.2 | 2.4 | 2.2 | 2.6 |

| Application 使用范围 | Impact area and taphole 迎钢面、出钢口修补 | Taphole 出钢口修补 | |||||

Send inquiry

Please Leave your message you want to know! We will respond to your inquiry within 24 hours!