Product detail

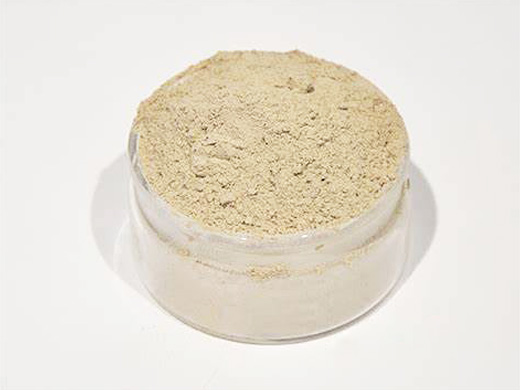

Blast-Furnace Plug

Main Composition:SiO2 + Al2O3

Application:Blast furnace

Capacity:1000 tons per month

Color:Black

Package:As your requirements

Product Introduction

For the production of blast furnace, the Blast-furnace Plug not only directly affects the normal production of the blast furnace, but also relates to the service life of the hearth. Good injection material, good opening, good sintering, short plugging time, no moisture, corrosion resistance, anti-scouring, stable iron running is the basic requirement for the Blast-furnace Plug.

Features

1.Good plasticity and sintering properties.

2.Corrosion-resistant, anti-scouring.

3.No harmful substances during usage.

Application

It is mainly used in the blast furnace.

Product Parameters

| Item | PN-1 | PN-2 | PN-3 | PN-4 | |

| Chemical Composition(%) | AL2O3 | 20 | 30 | 30 | 30 |

| SiC | 25 | 25 | 30 | 35 | |

| Si3N4 | — | — | 5 | 10 | |

| Bulk Density(g/m3) | 2.10 | 2.20 | 2.30 | 2.30 | |

| Linear Change(%) | 1300℃×3h | ±1.0 | ±1.0 | ±1.0 | ±1.0 |

| Modulus Rupture (Mpa) ≥ | 1300℃×3h | 2-5 | 2-5 | 2-5 | 2-5 |

| Cold Crushing Strength(Mpa) | 1300℃×3h | 6-12 | 6-12 | 6-15 | 6-15 |

| Volume of Furnace(m3) | ≦1000 | 1000-2000 | 2000-3200 | ≧2500 | |

Note: According to the actual situation and user needs, the data in the table can be adjusted appropriately. Carbide Water-based Blast-furnace Plug Technical Index:

| Item | Chemical Composition(%) | ||||||

| SiO2 | AI2O3 | ZrO2 | MgO | Fe2O3 | fixed carbon | loss on ignition | |

| Property Value | 30-35 | 18-20 | <0.5 | >0.2 | <2.5 | 35 | 40-45 |

Send inquiry

Please Leave your message you want to know! We will respond to your inquiry within 24 hours!