News detail

AZS Refractory Bricks: An In – depth Analysis

I. Introduction

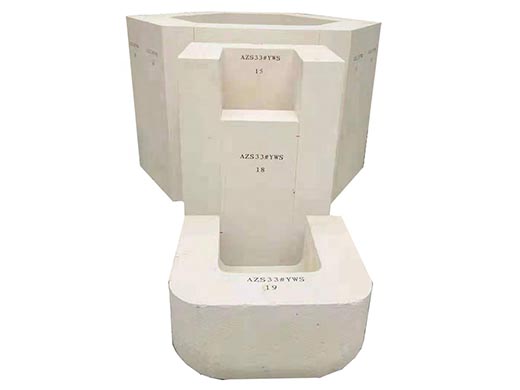

AZS refractory bricks are a type of high – performance refractory material that has extensive applications in various high – temperature industrial processes. AZS stands for Alumina – Zirconia – Silica, which indicates the main components of these bricks. The unique combination of these elements endows AZS refractory bricks with excellent thermal, mechanical, and chemical properties, making them indispensable in industries where high – temperature resistance and stability are crucial.

II. Composition and Structure of AZS Refractory Bricks

A. Alumina (Al₂O₃)

Alumina is a key component of AZS bricks, providing high – temperature strength and resistance to chemical corrosion. High – purity alumina can enhance the refractoriness of the bricks. It forms a stable crystal structure within the brick matrix, contributing to its overall mechanical stability under extreme thermal conditions.

B. Zirconia (ZrO₂)

Zirconia in AZS bricks has remarkable thermal shock resistance properties. It undergoes phase transformations during heating and cooling cycles, which can absorb and relieve thermal stresses. This property is vital in applications where rapid temperature changes occur, preventing the brick from cracking or spalling.

C. Silica (SiO₂)

Silica acts as a binder in the AZS brick system. It helps in holding the alumina and zirconia particles together, forming a cohesive structure. Additionally, silica can also influence the melting behavior and viscosity of the brick during the manufacturing process.

III. Manufacturing Process of AZS Refractory Bricks

A. Raw Material Preparation

- The first step in the production of AZS refractory bricks is the selection and preparation of high – quality raw materials. Alumina powder, zirconia powder, and silica powder with specific particle sizes and purities are carefully sourced. These powders are then mixed in precise proportions according to the desired composition of the AZS brick.

- Before mixing, the raw materials may undergo processes such as grinding and sieving to ensure uniform particle size distribution. This is crucial for obtaining a homogeneous brick structure and consistent properties.

B. Mixing

- The mixed raw materials are then placed in a mixing device. In modern manufacturing, high – energy mixers are often used to ensure thorough blending of the powders. Additives such as binders, plasticizers, or lubricants may also be added during this stage to improve the work-ability of the mixture.

- The mixing process needs to be carefully controlled to achieve the right consistency and homogeneity of the mixture. The duration of mixing, the speed of the mixer, and the order of adding the components are all factors that can affect the quality of the final product.

C. Molding

- After mixing, the refractory mixture is transferred to molds. The molding process can be carried out using various methods, such as pressing or casting. In pressing, the mixture is subjected to high pressure in a hydraulic or mechanical press to form the desired brick shape. Casting, on the other hand, involves pouring the mixture into molds and allowing it to solidify under controlled conditions.

- The design of the mold is critical as it determines the final shape and dimensions of the AZS brick. The mold should have smooth surfaces to ensure easy demolding and to obtain a good – quality finish on the brick.

D. Drying

- Once molded, the AZS bricks are dried to remove any moisture present in the mixture. Drying is usually carried out in drying chambers with controlled temperature and humidity. Slow and uniform drying is essential to prevent cracking or warping of the bricks.

- The drying temperature and time are carefully adjusted based on the size and thickness of the bricks. For larger and thicker bricks, a longer drying time may be required to ensure that the moisture is completely removed from the interior of the brick.

E. Firing

- After drying, the AZS bricks are fired in high – temperature kilns. The firing temperature can range from 1600 °C to 1800 °C or even higher, depending on the specific composition and quality requirements of the bricks. During firing, the chemical reactions among the raw materials are completed, and the brick structure is densified.

- The firing process is a critical stage in determining the final properties of the AZS refractory bricks. The heating rate, holding time at the maximum temperature, and cooling rate all need to be precisely controlled to achieve the desired microstructure and performance of the bricks.

IV. Applications of AZS Refractory Bricks

A. Glass Industry

- In the glass industry, AZS refractory bricks are widely used in glass melting furnaces. They are used to line the furnace walls, bottom, and other critical areas that are in direct contact with the molten glass. The high – temperature resistance and chemical stability of AZS bricks prevent them from reacting with the molten glass, ensuring the quality of the glass production.

- The excellent thermal shock resistance of AZS bricks allows them to withstand the temperature fluctuations during the glass melting and refining processes. This helps in maintaining the integrity of the furnace structure and reducing the need for frequent repairs and replacements.

B. Ceramic Industry

- In ceramic kilns, AZS refractory bricks are used to create a stable high – temperature environment. They are used in the construction of kiln car decks, sidewalls, and roofs. The ability of AZS bricks to resist high – temperature deformation and chemical attack ensures the uniform firing of ceramics.

- For ceramic products that require precise temperature control during firing, such as high – quality porcelain and technical ceramics, AZS refractory bricks provide the necessary thermal stability and insulation properties.

C. Metallurgical Industry

- In the metallurgical industry, AZS refractory bricks are used in various furnaces for smelting metals. For example, in steel – making furnaces, they are used to line the ladles and tundishes. The resistance of AZS bricks to molten metal corrosion and thermal shock helps in improving the efficiency of the metallurgical process and reducing metal losses.

- In non – ferrous metal smelting, such as aluminum and copper smelting, AZS refractory bricks are also used in different parts of the furnaces to withstand the high – temperature and corrosive environments created by the molten metals and slag.

V. Suitable Industrial Fields of AZS Refractory Bricks

A. High – Temperature Furnaces

- AZS refractory bricks are ideal for use in high – temperature furnaces in industries such as power generation, where coal – fired boilers or gas – fired furnaces operate at elevated temperatures. The ability of these bricks to maintain their structural integrity under extreme heat conditions ensures the safe and efficient operation of the furnaces.

- In industrial heat – treatment furnaces for metals and alloys, AZS refractory bricks provide the necessary thermal environment for processes like annealing, quenching, and tempering. Their stability and resistance to thermal degradation make them suitable for long – term use in these applications.

B. Chemical Processing Industry

- In the chemical processing industry, where reactors and kilns are used for chemical reactions at high temperatures, AZS refractory bricks can be used to line the reaction vessels. Their chemical resistance to various acids, Alkaline Earth, and other reactive chemicals in the process environment ensures the durability of the equipment.

- For example, in the production of cement, lime, and other building materials that involve high – temperature chemical reactions, AZS refractory bricks can be used in the kilns to withstand the harsh chemical and thermal conditions.

C. Aerospace and Defense

- In the aerospace and defense industries, there are applications where high – temperature and high – performance refractory materials are required. Although not as common as in traditional industries, AZS refractory bricks can be used in certain specialized equipment such as high – temperature test chambers for aerospace materials or in some defense – related thermal management systems.

- Their ability to withstand extreme temperatures and harsh environments makes them potential candidates for future developments in these high – tech industries.

VI. Conclusion

AZS refractory bricks are a remarkable type of refractory material with their unique composition and excellent properties. The complex manufacturing process ensures their high quality and performance. Their wide range of applications in industries such as glass, ceramic, metallurgical, and various high – temperature processing industries highlights their importance. As technology continues to advance, the demand for even higher – performance AZS refractory bricks may increase, driving further research and development in this field to meet the evolving needs of different industrial applications.

Send inquiry

Please Leave your message you want to know! We will respond to your inquiry within 24 hours!